1 understanding o2 sensor signals. Its voltage depends on the amount of oxygen in the exhaust stream. The sensor’s output voltage should go up and down accordingly; Open and close the engine throttle with a quick motion. 4 common o2 sensor voltage patterns.

4 common o2 sensor voltage patterns. One of the most common bad oxygen sensor symptoms is a check engine light on your dashboard. One or two wire unheated oxygen sensors should be inspected or replaced every 30,000 miles. Web oxygen sensor failure can often be traced to one of three common factors: In case it is not within range, there is either an engine problem (loose hose) or the o2 sensor is bad.

If it is within this range, the o2 sensor is operating normally, and you can stop testing. One of the most common bad oxygen sensor symptoms is a check engine light on your dashboard. A faulty o2 sensor can’t monitor the fuel and oxygen mixture in your engine, which can cause the check. In essence, this could mean that there’s an excess of oxygen in comparison to fuel in the combustion chamber. The sensor’s output voltage should go up and down accordingly;

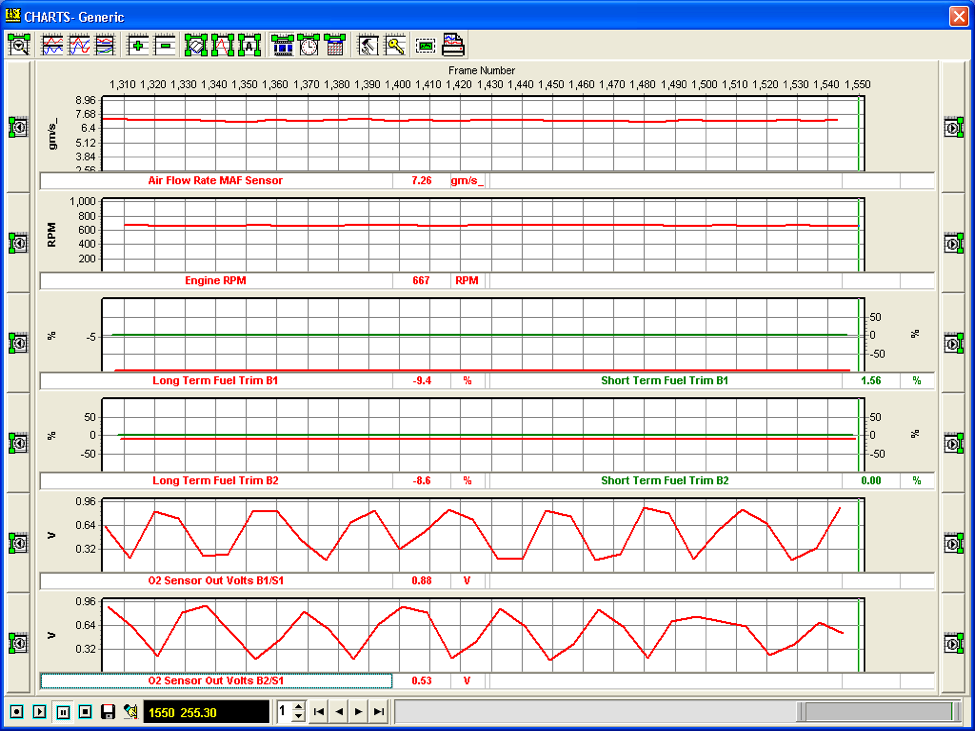

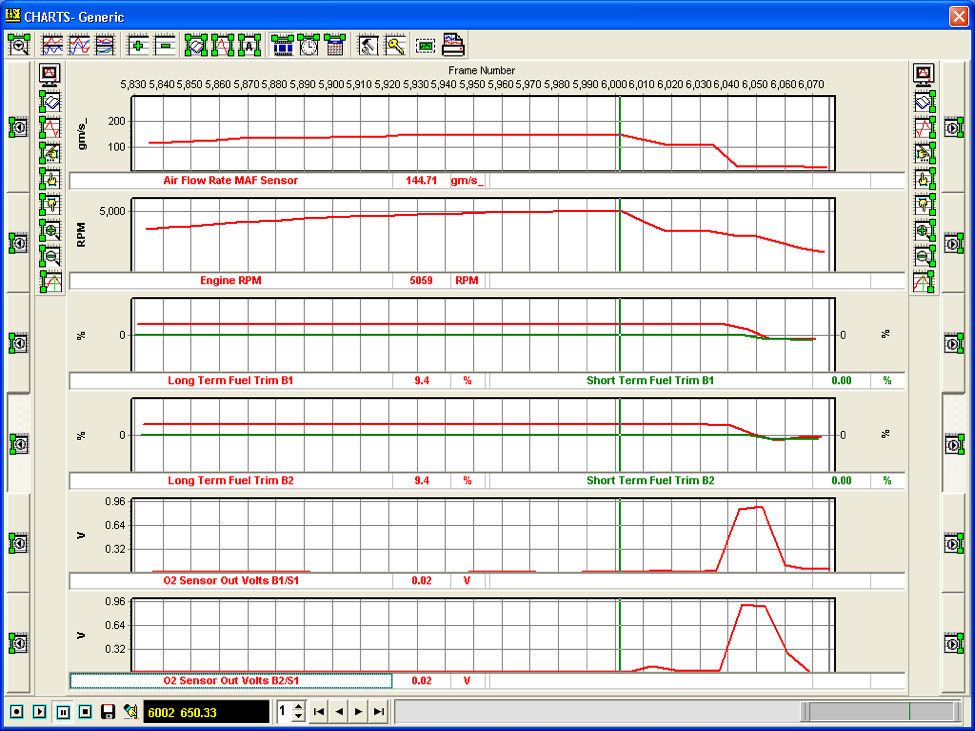

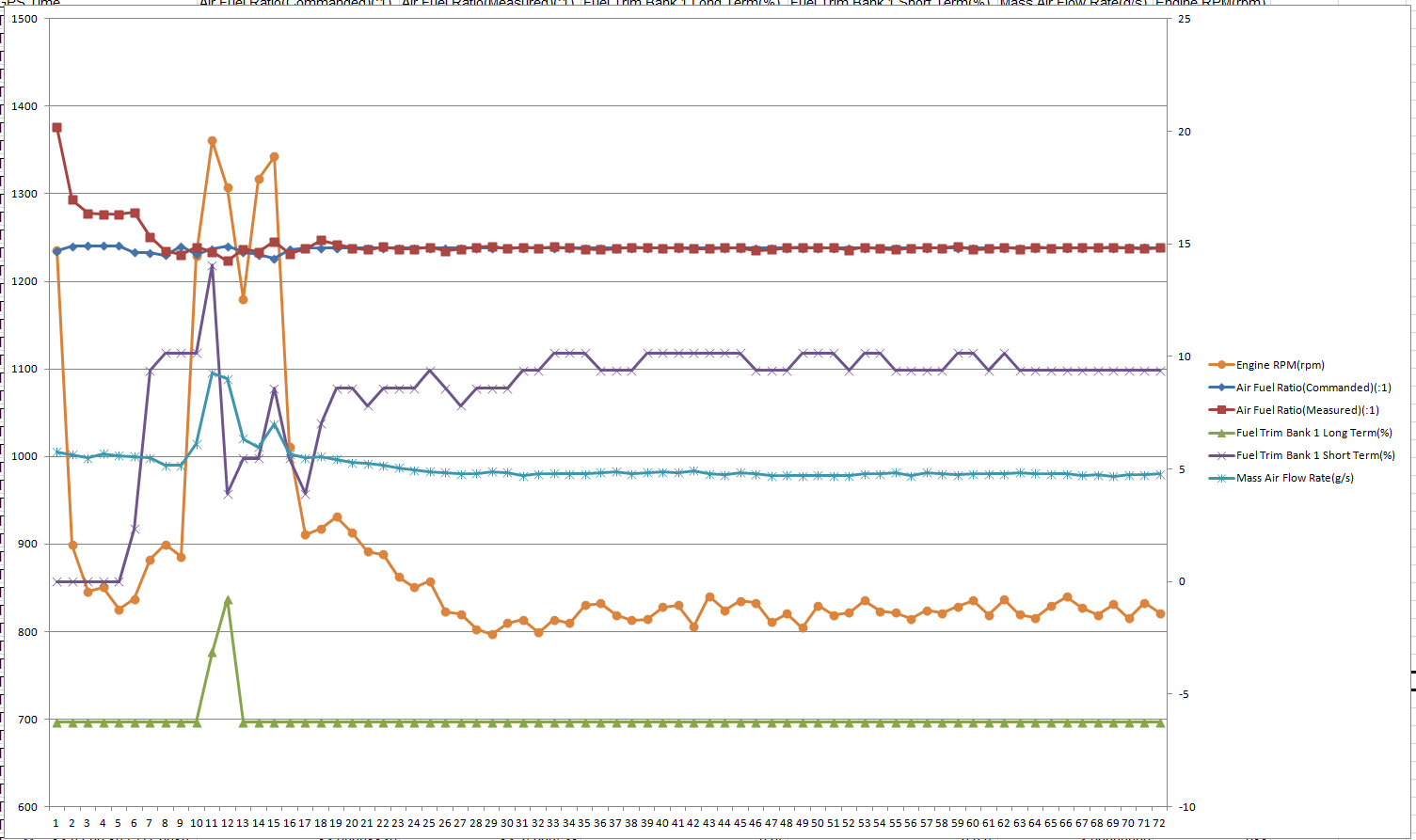

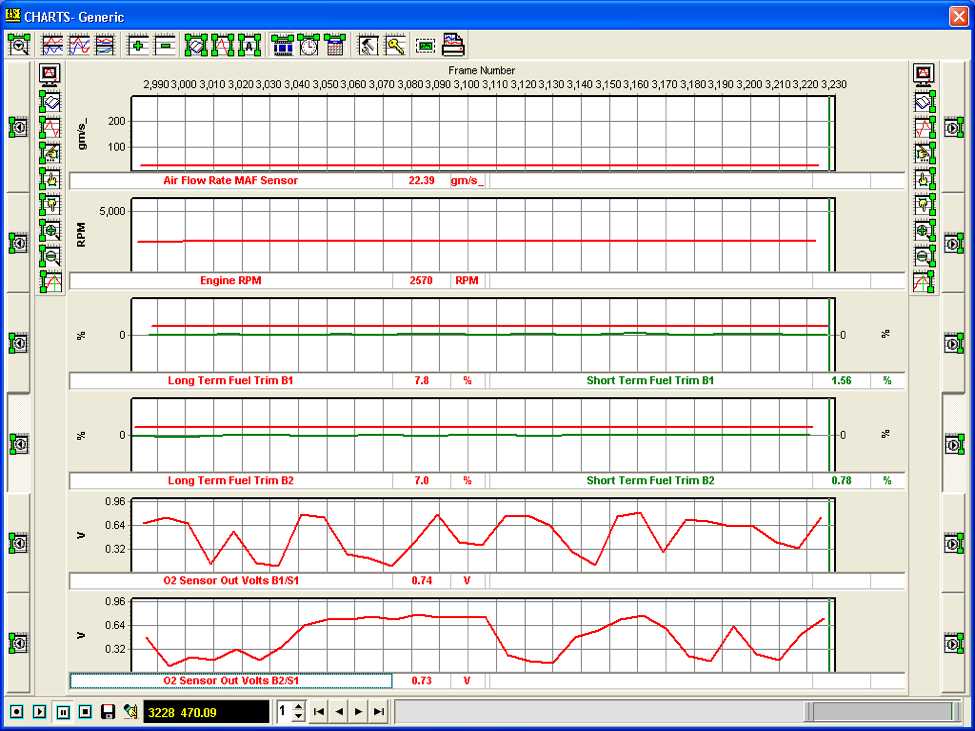

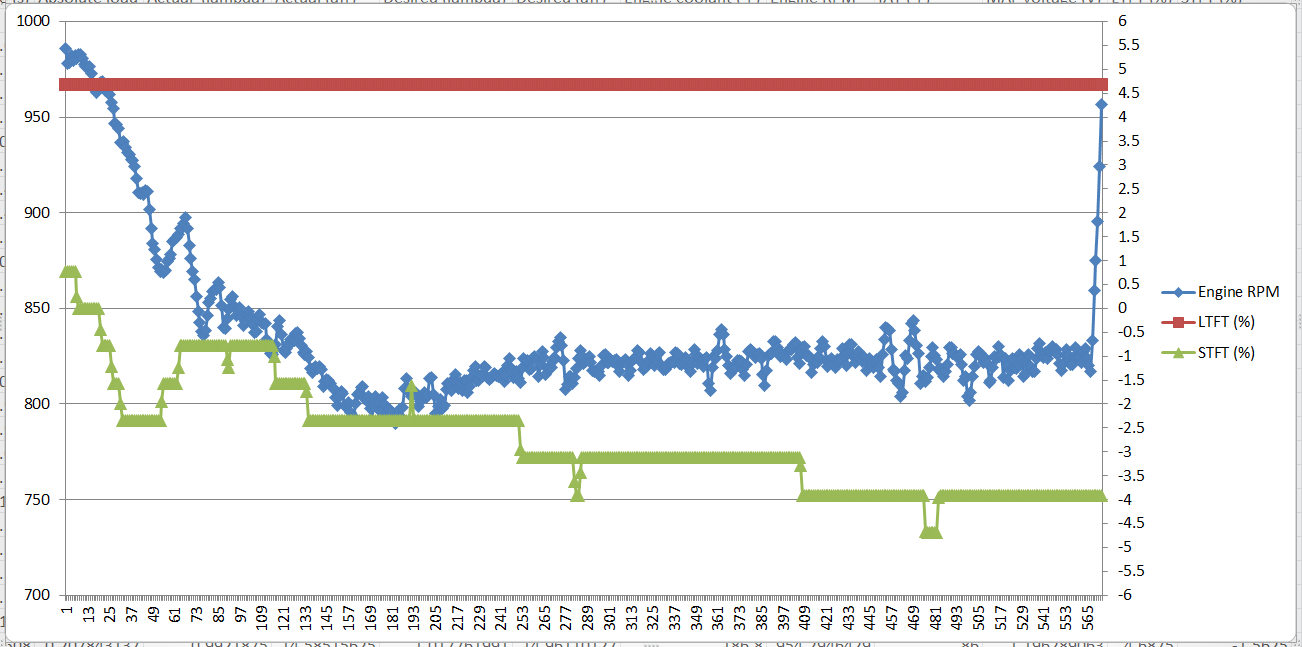

Web the o2 sensor can be considered a small battery that has an operating range of 0 to 1 volt when fully warmed up to 600°f. 7 optimizing engine performance with o2 sensor signals. Web oxygen sensors detect the amount of oxygen content in the exhaust stream and turn this information into a voltage signal that your car computer uses to control fuel ratio and emissions. Web the voltage readings from your o2 sensor should fluctuate rapidly between 0.1 and 0.9 volts. What are the diagnostic clues that indicate a malfunctioning o2 sensor? In essence, this could mean that there’s an excess of oxygen in comparison to fuel in the combustion chamber. All o2 sensors are vented to the atmosphere which. But you can try some useful tips below to eliminate the code: Open and close the engine throttle with a quick motion. Web what are some common o2 sensor voltage readings and their meanings? First, clean your maf and check your air filter as well as vacuum leaks. Web the o2 sensor voltage should range from 100mv to 900mv with an average of 450mv the pcm power train control module will consider this a proper operating range. Its voltage depends on the amount of oxygen in the exhaust stream. A higher voltage means there is too much fuel in the mixture. If it is within this range, the o2 sensor is operating normally, and you can stop testing.

Now, What Should You Do If The Downstream O2 Sensor Is Bad?

If it is within this range, the o2 sensor is operating normally, and you can stop testing. Web start vehicle and warm engine up to operating temperature. In essence, this could mean that there’s an excess of oxygen in comparison to fuel in the combustion chamber. Web typically, a fully operational o2 sensor should fluctuate between 0.1 and 0.9 volts.

Web Sudden Catalytic Converter Failure.

2 interpreting o2 sensor voltage. 3 the role of o2 sensors in fuel efficiency. Goes above this range, remains below 0.5 volts; Because all combustion engines need a mix of oxygen and fuel to run, it is essential that we can track the fuel/oxygen ratio to give it the best working condition.

Diagnostic Trouble Codes (Dtc), Rough Idling, And Elevated Fuel Consumption Are Key Indicators Of O2 Sensor Issues.

If the voltage readings remain steady or do not fluctuate enough, it could indicate a faulty sensor. 1 understanding o2 sensor signals. Web if the o2 sensors, catalytic converter, or fuel injectors are damaged the downstream o2 sensor voltage could be higher or lower. The time taken for the voltage to change from 0.1 v to 1.0 v (referred to as the lean to rich response time) should be about 300 milliseconds.

A Steady Voltage Reading Could Mean That The Sensor Is Stuck In One Position, While A Lack Of Fluctuation Could Mean That The Sensor Is Not Receiving.

Stays fixed at a particular voltage; Web some of the symptoms of a bad oxygen sensor include a noticeable decrease in fuel economy along with a rich mixture. Web oxygen sensors detect the amount of oxygen content in the exhaust stream and turn this information into a voltage signal that your car computer uses to control fuel ratio and emissions. One or two wire unheated oxygen sensors should be inspected or replaced every 30,000 miles.