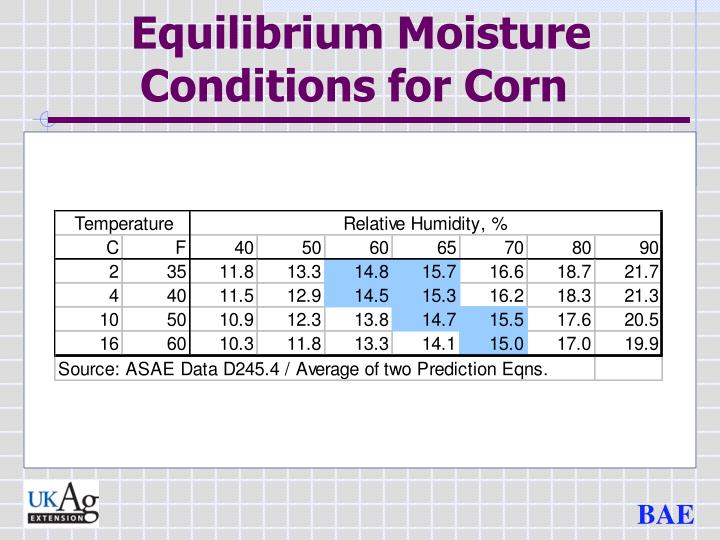

The midwest corn sweat factor can boost. But what is the right time for your corn crop? This tool offers predictions of corn drydown in the field using algorithms developed for the northern corn belt. Measure the initial moisture content of grain to be dried. Corn with 25% initial moisture and 15.5% (final moisture) after drying has a moisture shrink of 11.24%.

Grain moisture shrinkage is an important concept in grain marketing as this impacts the buying price and discounts. Web in general, drying corn from 30% down to 25% moisture requires about 30 gdus per point. Corn producers are faced with a variety of choices when it comes to marketing their crop. In addition to selecting a location and date, they also have several options related to the moisture level at which they deliver their grain. Web get tips on how to calculate corn moisture shrink and total shrink.

To optimize economic returns, understanding shrinkage and drying costs calculations are critical. The midwest corn sweat factor can boost. Water the soil thoroughly at planting and keep it evenly moist until germination occurs. The tool can help you plan logistics and assess risk by estimating the changes in grain moisture content that are likely to occur under a set of field conditions. This tool offers predictions of corn drydown in the field using algorithms developed for the northern corn belt.

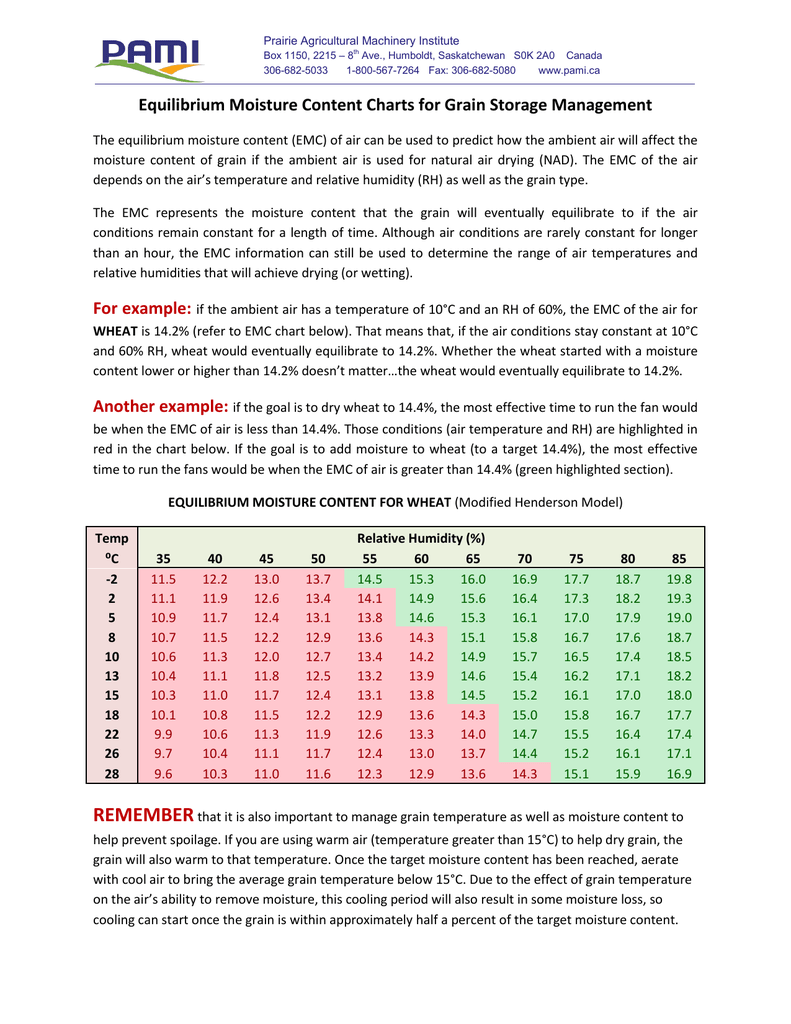

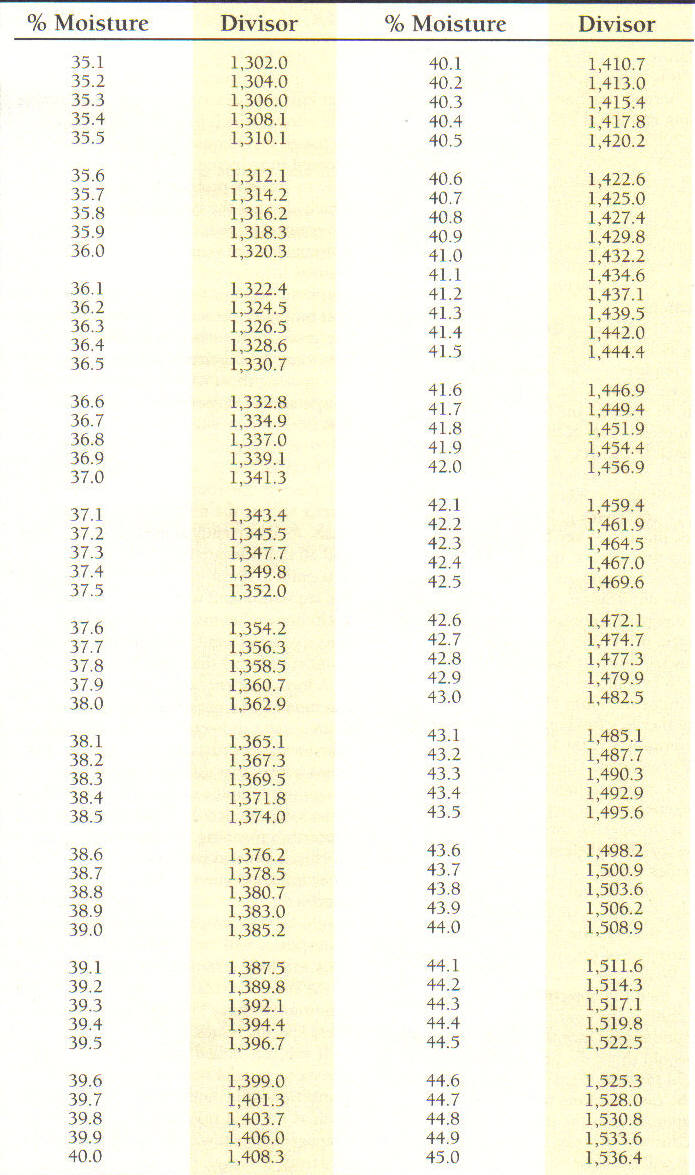

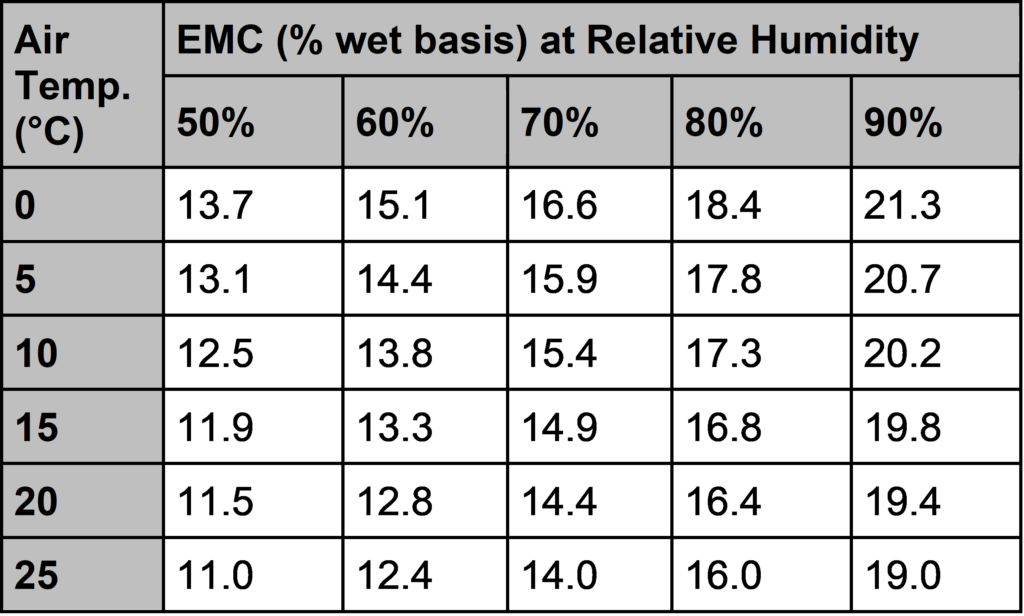

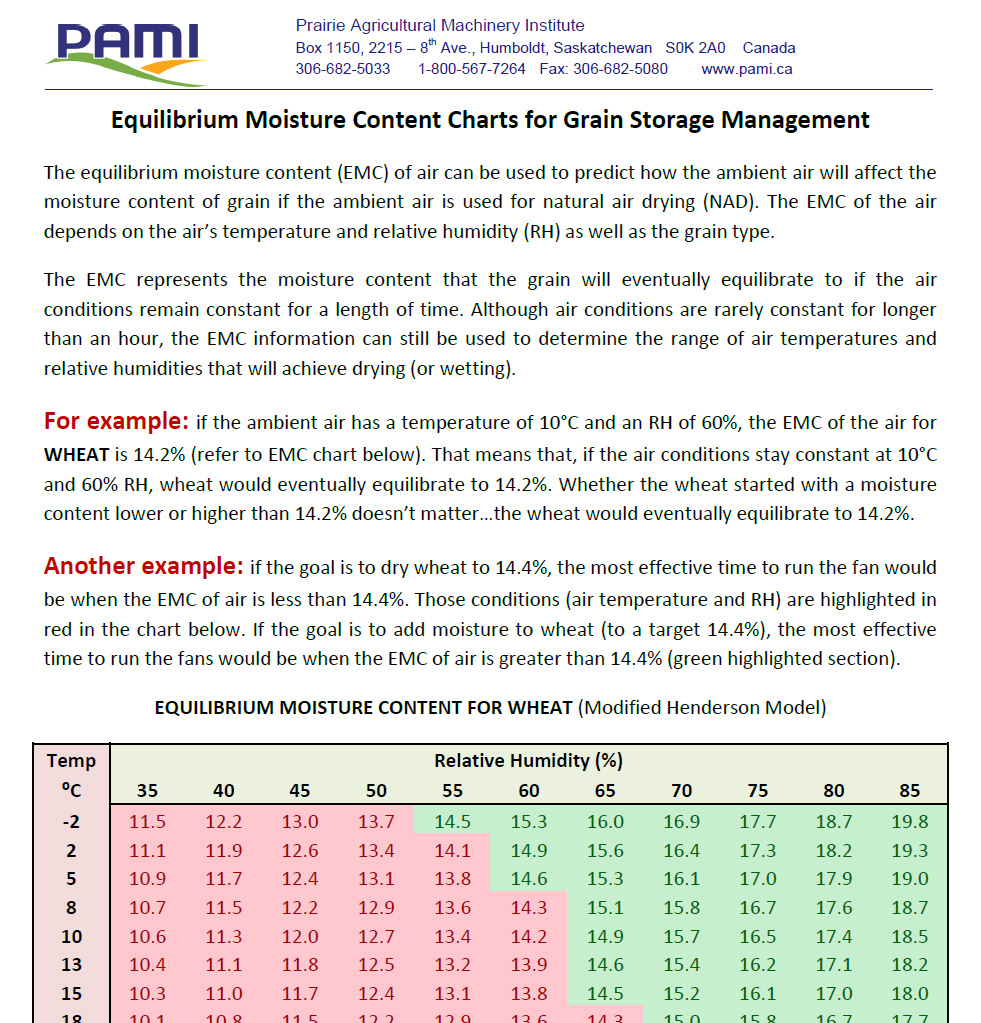

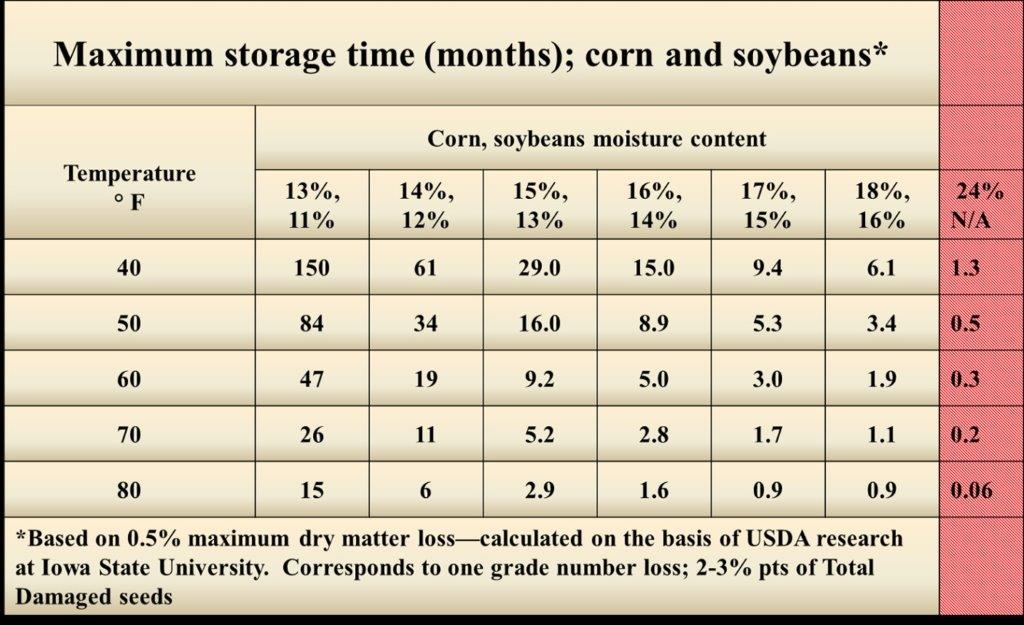

Web the key to achieving the former, and not the latter, is to thicken your fruit pie filling correctly. Web in general, drying corn from 30% down to 25% moisture requires about 30 gdus per point. Web corn moisture corrections. Web figure 1 shows a chart of shrinkage and drying costs based on the grain moisture at harvest and the costs of propane and electricity. The midwest corn sweat factor can boost. Essentially, this means adding a starch that can soak up the liquid released by the fruit as it bakes, lending structure to the fruit and helping it set in the oven. Web moisture shrink can be calculated by the following formula: To optimize economic returns, understanding shrinkage and drying costs calculations are critical. In addition to selecting a location and date, they also have several options related to the moisture level at which they deliver their grain. Web moisture shrink drying moisture shrink drying moisture shrink drying moisture shrink drying 14.5 How to identify successful germination What moisture level is best for harvest? Web the chart on the next three pages outlines the moisture specifications and, if the model 919/3.5’ moisture meter is used, the conversion table number and representative portion required to determine the moisture content of each type of grain is provided. Ample rainfall, good soil moisture, and above average normalized difference vegetation index (ndvi) indicate above trend yield. This tool offers predictions of corn drydown in the field using algorithms developed for the northern corn belt.

Web Corn Moisture Corrections.

How to identify successful germination Farmers in western and southern plains states are likely to harvest corn at 15 to 18 percent moisture. Web in general, drying corn from 30% down to 25% moisture requires about 30 gdus per point. Measure the initial moisture content of grain to be dried.

Ample Rainfall, Good Soil Moisture, And Above Average Normalized Difference Vegetation Index (Ndvi) Indicate Above Trend Yield.

Evans, r.l nielsen, and c.b. What moisture level is best for harvest? Southard agronomy department, purdue university corn is defined as any grain consisting of 50 percent or more whole kernels of shelled dent corn and/or flint corn. Expected corn yields based on planting dates.

1 − [ (100 − Initial Moisture) ÷ (100 − Final Moisture) ] × 100%.

Using a sling psychrometer (figure 4), determine the wet and dry bulb temperatures. Web barchart’s machine learning forecast models are predicting record corn yield, 189 bushels/acre, and record soybean yield, 54 bushels/acre. Web as grain is dried, moisture is removed from the grain by evaporation, which results in a loss of volume (fewer bushels) and a weight loss (fewer pounds) of grain. In addition to selecting a location and date, they also have several options related to the moisture level at which they deliver their grain.

Usually, The Combination Of The Two Makes For A Very Steamy Situation.

To use it, follow these simple steps: It is still early and there is a… Web figure 1 shows a chart of shrinkage and drying costs based on the grain moisture at harvest and the costs of propane and electricity. Drying from 25% to 20% requires about 45 gdus per point (lauer, 2016).