Web most specifications for rotor thickness are found in the “base brake” articles. Web rotors have a minimum thickness that is typically written on the side of the rotor. Web the minimum thickness for general inspection (motor vehicle inspection) is defined as follows: Web with the micrometer, measure the brake rotor thickness 10mm into the outer circumference of the rotor. Disc brake rotor minimum thickness (rmt) is the minimum safe working thickness of a rotor.

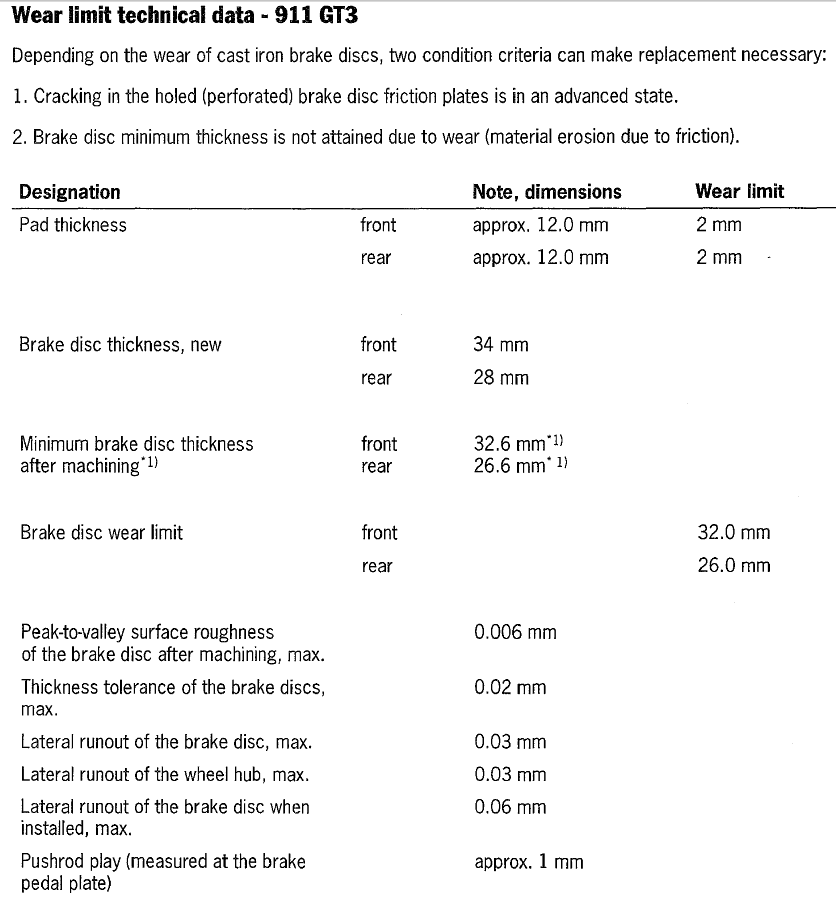

The lowest value should be used as reference for the entire rotor. These specifications are typically found in your vehicle’s owner’s manual or the vehicle’s repair manual or stamped directly on the rotor. Does anyone know what the minimum pad and rotor thickness for the front and rear brakes are for the accent? When a disc rotor reaches rmt it must be replaced. As shown here in figure 1 the base brake article contains a section titled technical specifications.

Discard thickness the discard thickness of a rotor is the thickness at which the rotor should be replaced. See if the measurements are above the minimum thickness. Hey everyone, i'm swapping my summer tires back on to the car on sunday, and i wanted to take a look at the brakes while i had the wheels off. Continued operation at or below rotor minimum thickness can lead to brake system failure. Also look for disc thickness variation.

Web most specifications for rotor thickness are found in the “base brake” articles. Nominal size thickness minus 1.6 mm. The lowest value should be used as reference for the entire rotor. Measure the rotor again 7 more times, at every 45 degrees. Web the brake rotor minimum thickness chart is designed to help you determine the minimum thickness your rotors should be in order to be safe and effective for use. Web the minimum thickness for general inspection (motor vehicle inspection) is defined as follows: See if the measurements are above the minimum thickness. Web the average difference between nominal and machine to thickness is.050″ to.060″. These specifications are typically found in your vehicle’s owner’s manual or the vehicle’s repair manual or stamped directly on the rotor. Web disc brake rotor minimum thickness (also known as scrap thickness) is the minimum safe working thickness of a rotor at which it must be replaced. Web rotors have a minimum thickness that is typically written on the side of the rotor. This section usually contains a chart indicating all. Web measure rotor disc thickness at a minimum of six locations, but preferably at eight equidistant points along the rotor — at 12 o'clock, 45 degrees, 90 degrees, 135 degrees, 180 degrees, 225 degrees, 270 degrees. As the rotor reaches its minimum thickness, the braking distance increases, sometimes up to 4 meters. Measurements vary from 1.7mm to 1.5mm.

*** 0.807” On 18” Premium Brakes.

As shown here in figure 1 the base brake article contains a section titled technical specifications. Developed and manufactured under iso/ts 16949 standards. When a disc rotor reaches rmt it must be replaced. Refer to relevant service information for unknown vehicles.

The Lowest Value Should Be Used As Reference For The Entire Disc.

Web disc brake rotors explained | how to find the right rotor for your bike | bikeradar. Continued use of disc rotors below rmt can lead to brake system failure. Web follow specific steps and guidelines to accurately measure rotor thickness using a micrometer. Continued operation at or below rotor minimum thickness can lead to brake system failure.

Different Brands Recommend Different Minimum Thicknesses So Check The Details For The Rotors You Use.

Web rotors have a minimum thickness that is typically written on the side of the rotor. Measurements should be taken in at least 4 different points. If your rotor has worn past this thickness or needs to be cut, you need new rotors. This is usually found on the hat (the central portion of the rotor), within the cooling veins, or on the outer edges.

Road And Gravel Specific Rotors.

Disc brake rotor minimum thickness (rmt) is the minimum safe working thickness of a rotor. Measurements should be taken in at least 4 different points. As the rotor reaches its minimum thickness, the braking distance increases, sometimes up to 4 meters. Web to measure your rotor’s minimum operational thickness, place a micrometer at the thinnest point on the rotor’s surface where it meets the brake pads.