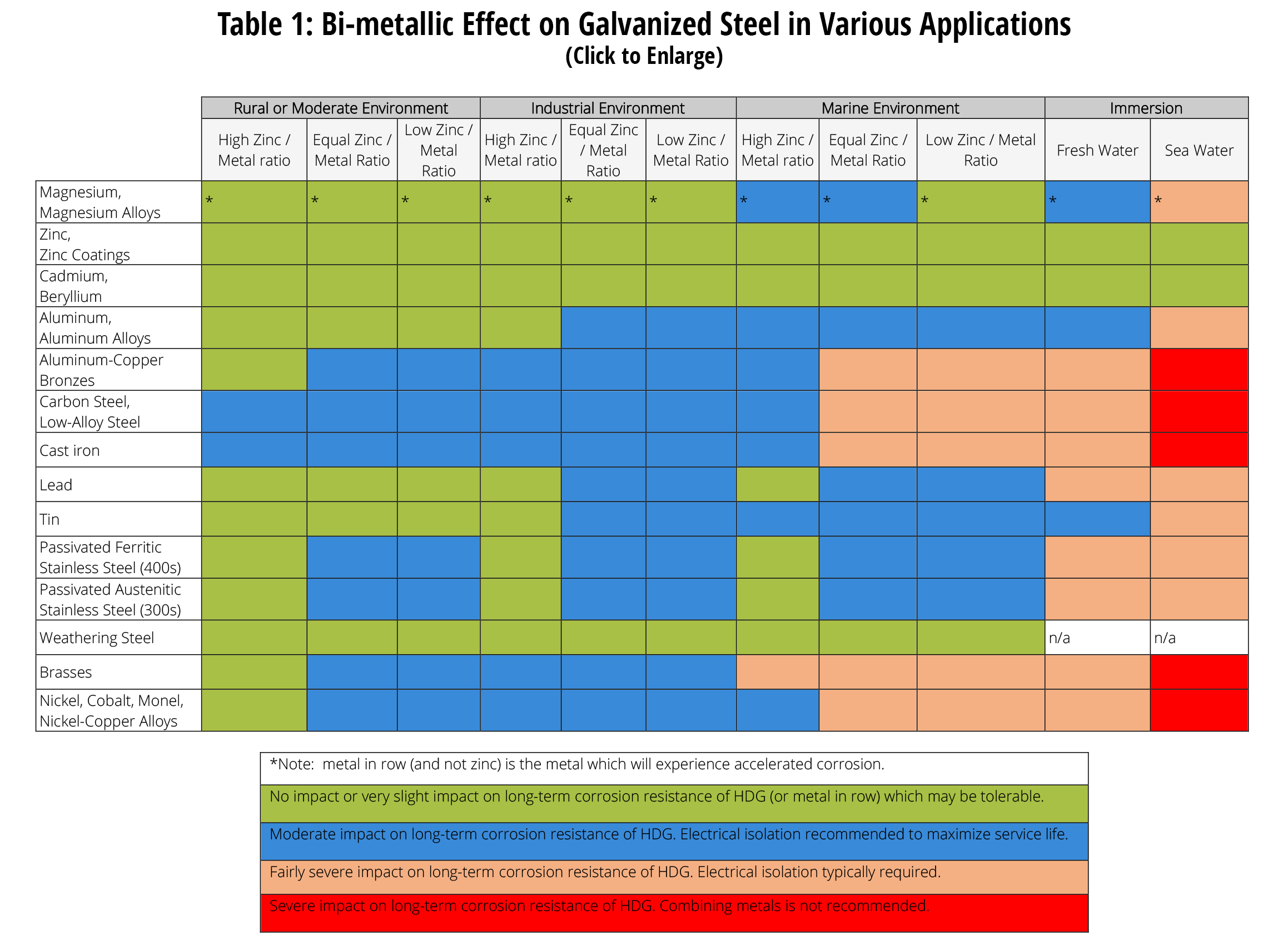

There are three conditions that must exist for galvanic corrosion to occur. Web when design requires that dissimilar metals come in contact, galvanic compatibility can be managed by finishes and plating which protects the base materials from corrosion. Web this slide includes a chart of galvanic corrosion potential between common construction metals. Weathertight warranties are also available. When dissimilar metals are used together in the presence of an electrolyte, separate them with a dielectric material such as insulation, paint or similar surface coating.

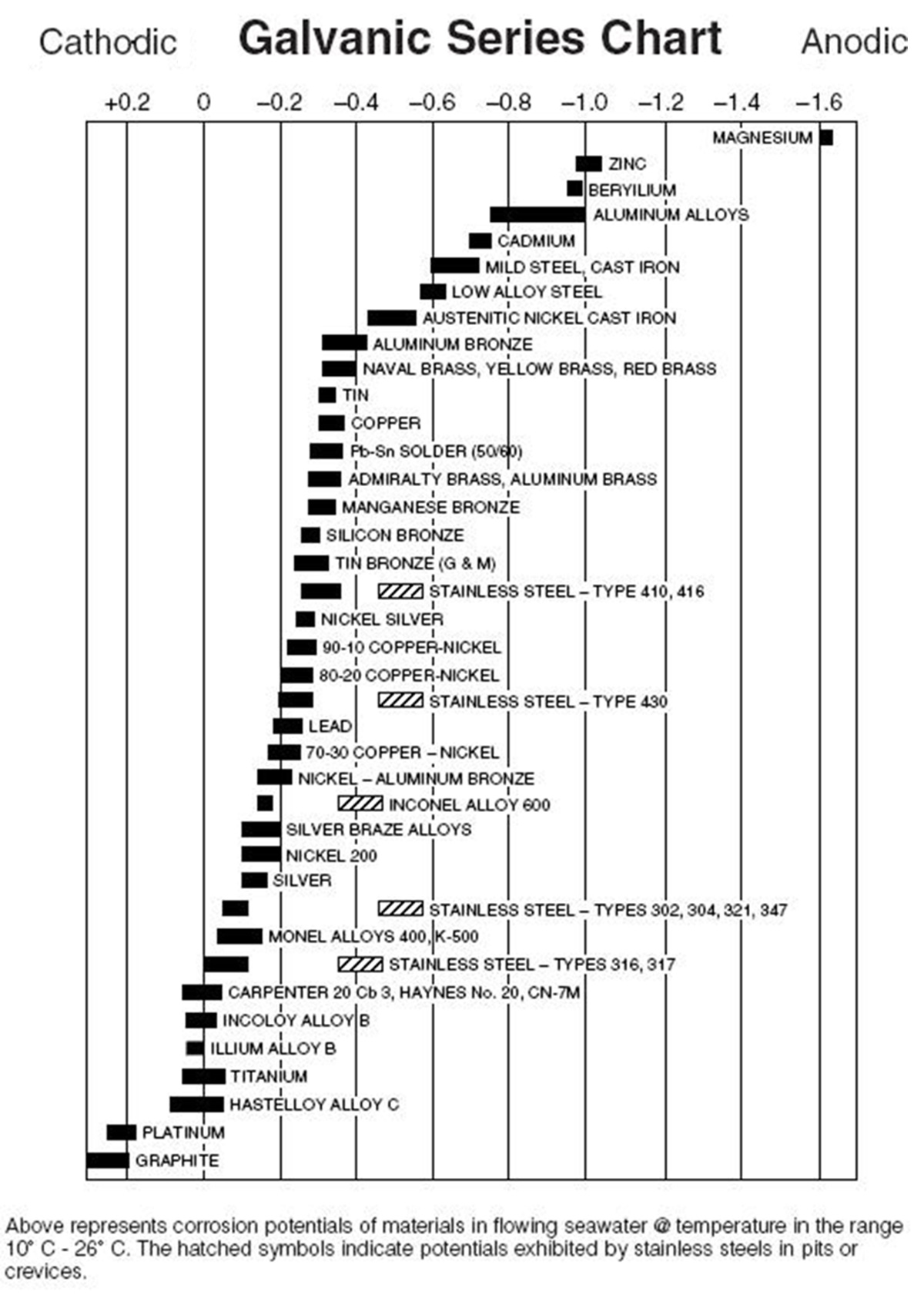

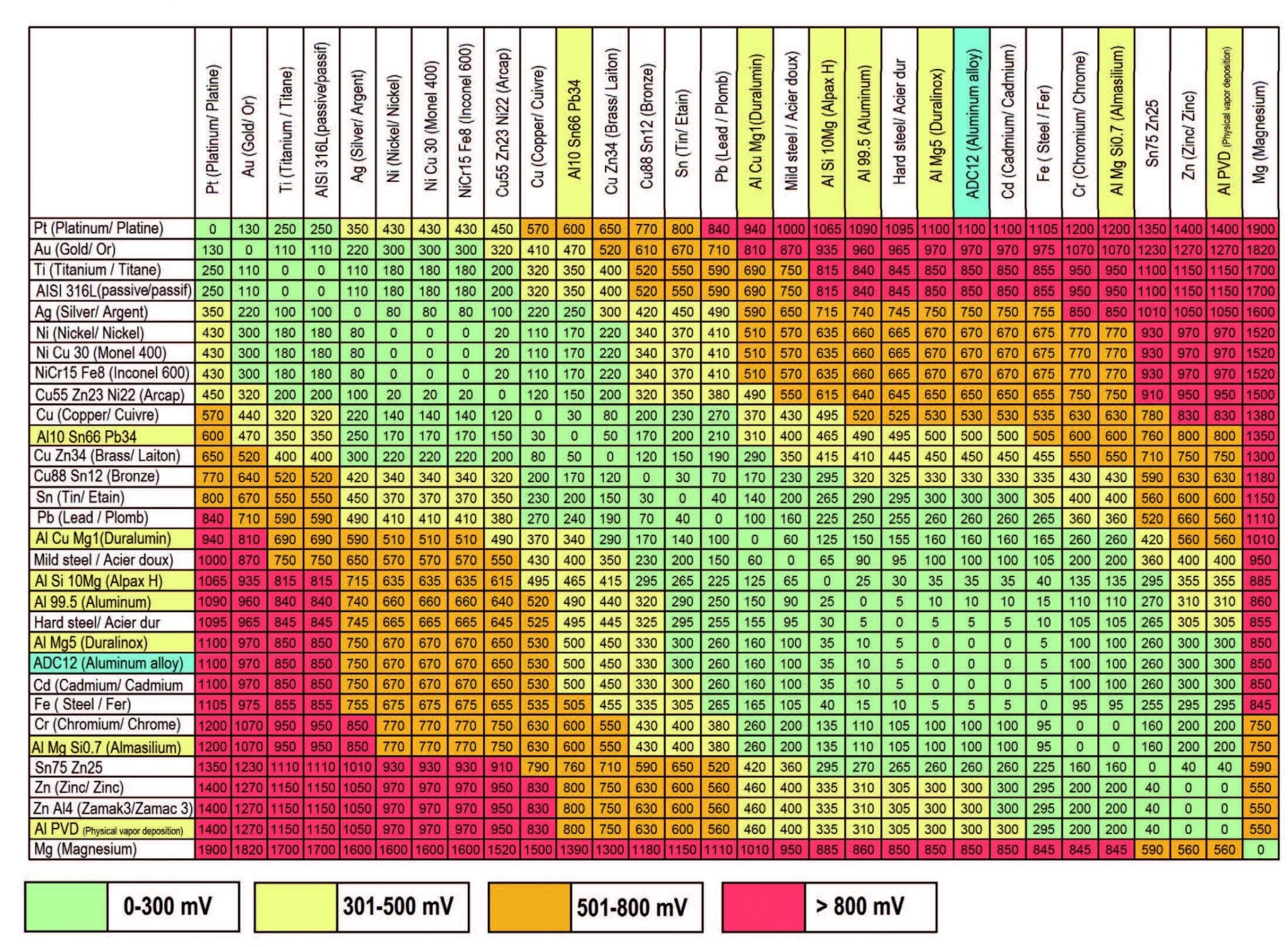

Web the susceptibility of different base metals to corrosion while in contact depends upon the difference between the contact potentials or the electromotive voltages of the metals involved. Web below is a galvanic reaction chart for dissimilar metals. A typical rule of thumb is that voltage differences of 0.2 volts or more suggest a galvanic corrosion risk. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Web read on to find out about what it is and how to use it to analyse the compatibility of joining metals.

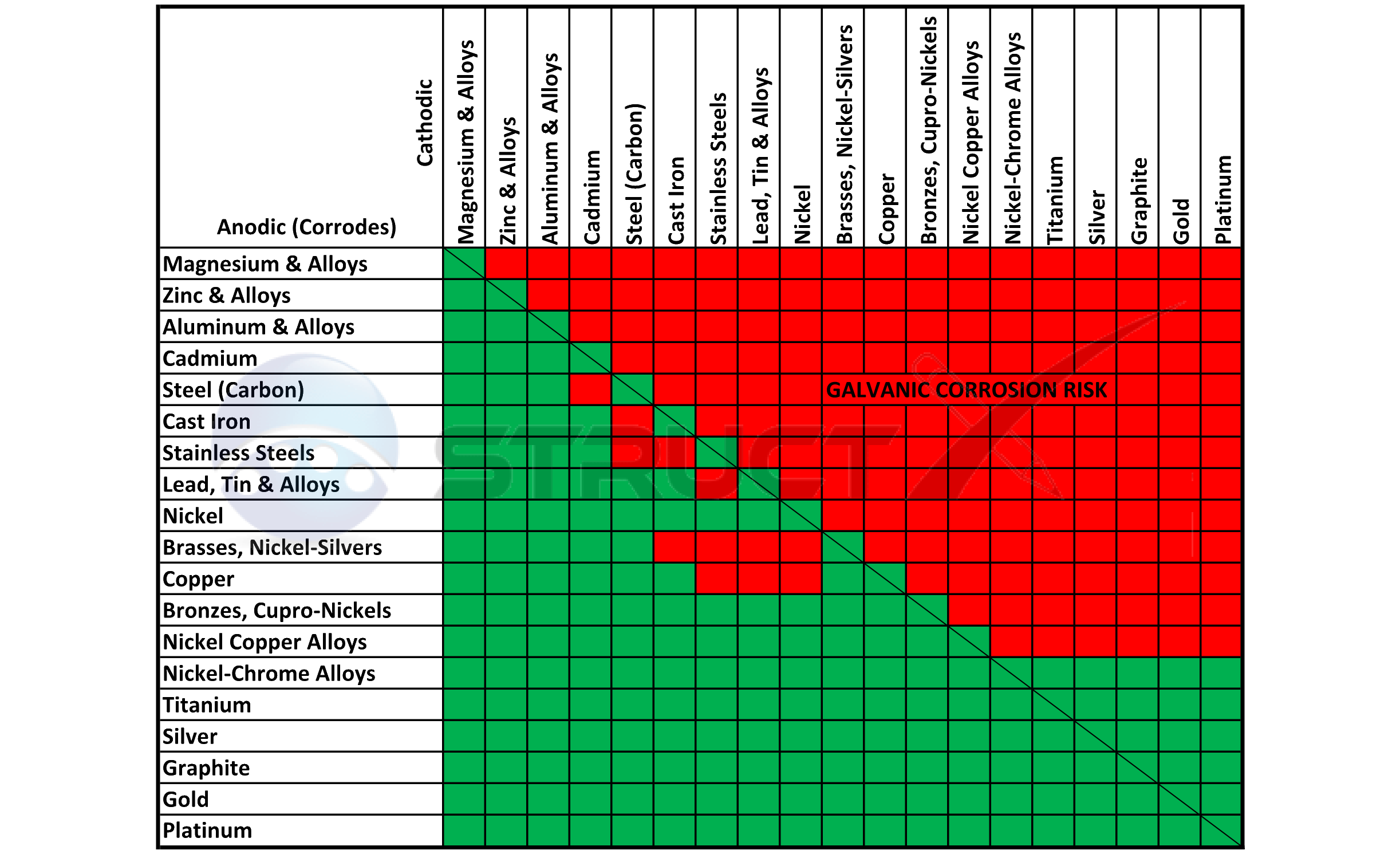

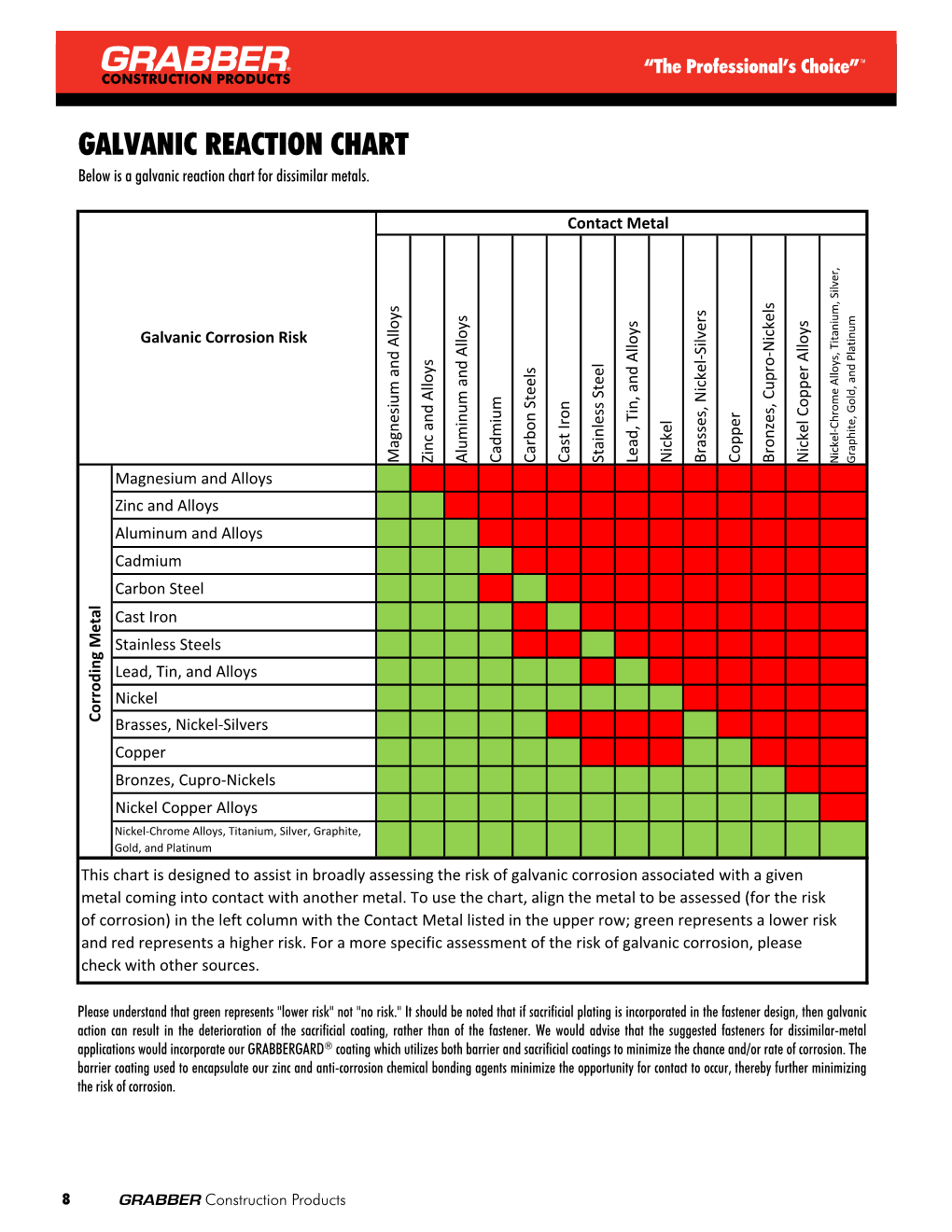

Web this article examines how dissimilar metals can lead to galvanic corrosion. Web choosing the right size or area of the joined metals: Web galvanic corrosion occurs when two dissimilar metals with different potentials are placed in electrical contact in an electrolyte. Web our extensive testing and independent certification program provide our customers access to over 40 florida product approvals on 11 different metal panel profiles. Web below is a galvanic reaction chart for dissimilar metals.

This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming into contact with another metal. Web we are aa metals, inc, one of north america’s largest master distributors of quality aluminum and stainless products. We also provide other helpful methods for avoiding galvanic corrosion. Electrolytic corrosion (electrolysis) occurs when dissimilar metals are in contact in the presence of an electrolyte, such as water (moisture) containing very small amounts of acid. Web below is a galvanic reaction chart for dissimilar metals. This type of accelerated corrosion between dissimilar metals is referred to as galvanic corrosion. There are three conditions that must exist for galvanic corrosion to occur. A typical rule of thumb is that voltage differences of 0.2 volts or more suggest a galvanic corrosion risk. Web this article examines how dissimilar metals can lead to galvanic corrosion. Web when design requires that dissimilar metals come in contact, galvanic compatibility can be managed by finishes and plating which protects the base materials from corrosion. First there must be two electrochemically dissimilar metals present. You can also learn more about overcoming potentially compatibility issues between metals. This conversion resource can help you determine what metal gauge you may need. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Web our extensive testing and independent certification program provide our customers access to over 40 florida product approvals on 11 different metal panel profiles.

Web Below Is A Galvanic Reaction Chart For Dissimilar Metals.

Web galvanic corrosion potential is a measure of how dissimilar metals will corrode when placed against each other in an assembly. When dissimilar metals are used together in the presence of an electrolyte, separate them with a dielectric material such as insulation, paint or similar surface coating. • harsh environments, such as outdoors, high humidity, and salt environments. Web we are aa metals, inc, one of north america’s largest master distributors of quality aluminum and stainless products.

The Greater The Potential Difference Is, The Greater The Tendency For Corrosion.

Web galvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. We also offer technical support including easy access to installation guides, product literature, technical bulletins and color charts. Web below is a galvanic reaction chart for dissimilar metals. Web our extensive testing and independent certification program provide our customers access to over 40 florida product approvals on 11 different metal panel profiles.

Web Galvanic Or Dissimilar Metal Corrosion Is Electrochemical Corrosion That Occurs When One Metal Comes In Contact With Another Material.

Web when two different metals are in contact and exposed to a common electrolyte, one of the metals experiences accelerated corrosion while the other is protected. Web this slide includes a chart of galvanic corrosion potential between common construction metals. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal combinations. Web galvanic corrosion occurs when two dissimilar metals with different potentials are placed in electrical contact in an electrolyte.

We Also Provide Other Helpful Methods For Avoiding Galvanic Corrosion.

First there must be two electrochemically dissimilar metals present. This type of accelerated corrosion between dissimilar metals is referred to as galvanic corrosion. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Web but when you step onto a jobsite, working with dissimilar metals turns into a whole new monster with dire potential consequences.