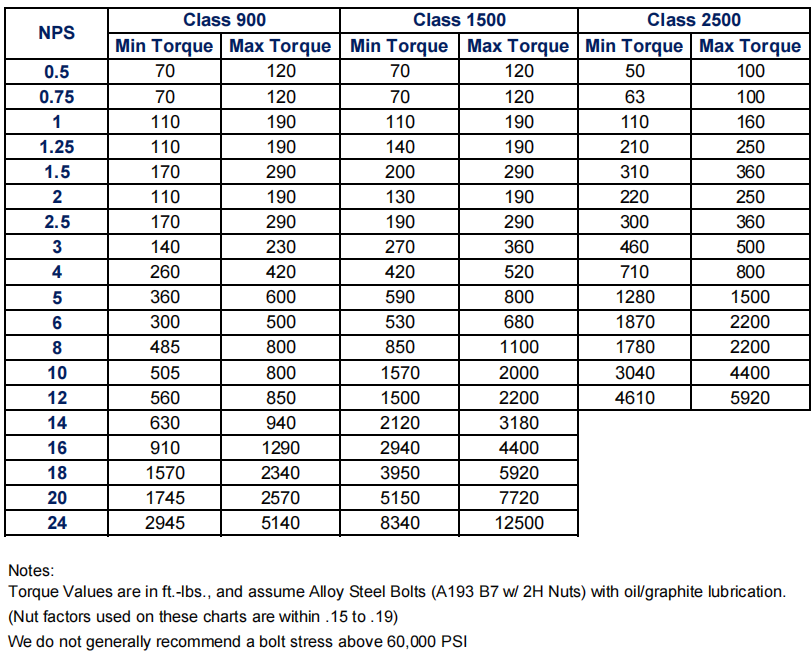

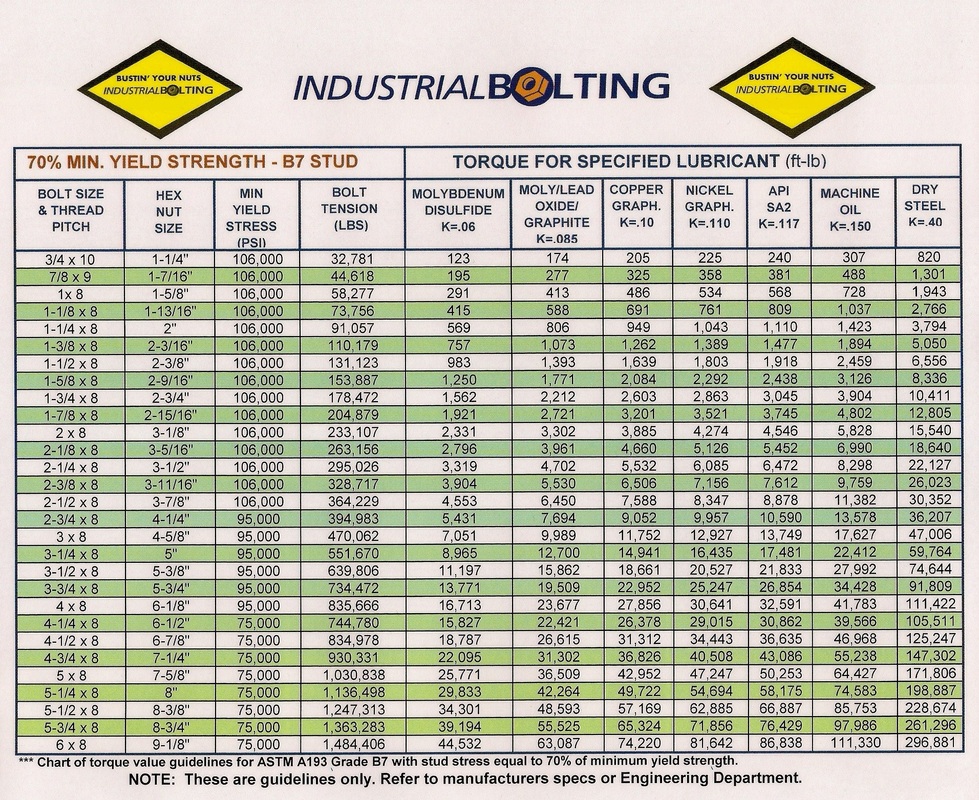

X pitch x bolthole o.d. The above table is applicable only for astm a320 grade b8, class 2 and a193 grade b8, class 2 stud bolts. The conventional way to achieve that load is by applying a measured torque to the flange bolts. Web bolt yield should be at least 80,000 psi. Web class 2500 flange torque charts listed by nominal pipe size.

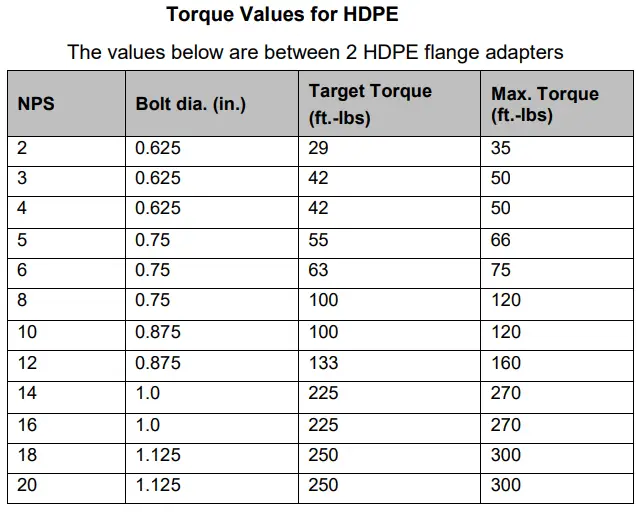

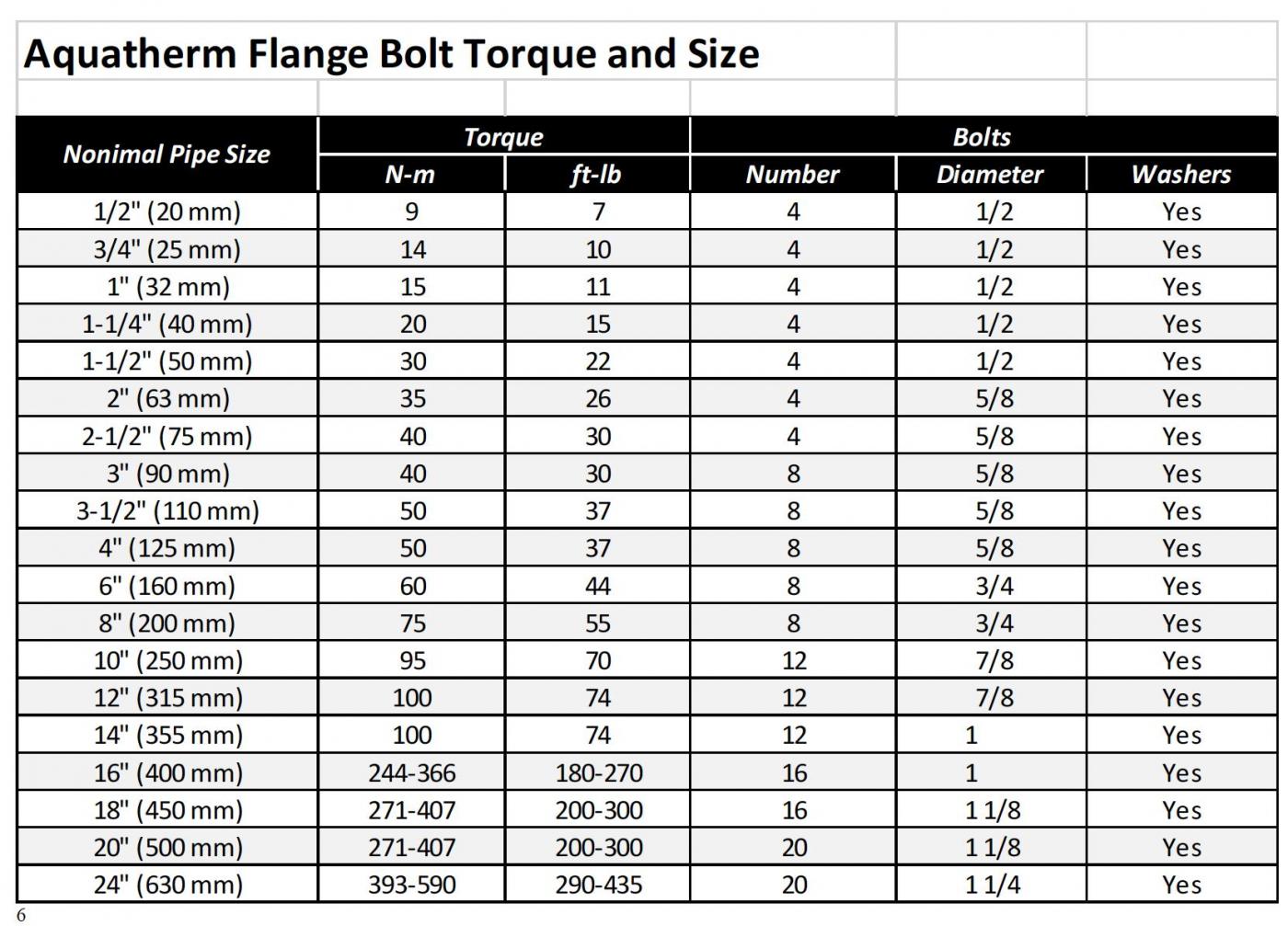

Lbs ansi 150# flanges ansi 300# flanges ansi 600# flanges rec. Web bolt yield should be at least 80,000 psi. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according to the national boiler code, installed in accordance with the central plastics company flange installations guidelines. These are 304 ss material. Web in this article, we will learn the basics of flange bolt torque calculation and some of the typical torque values in a chart format.

2245 psi ***ramco®manufacturing does not take any responsibility for any of these torque values, they are theoretical values & should be utlilized for reference only. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); Web a successful flange installation requires the proper amount of load applied to the gasket. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Web flange joints require proper tightening to avoid the leak of the fluid from the joint.

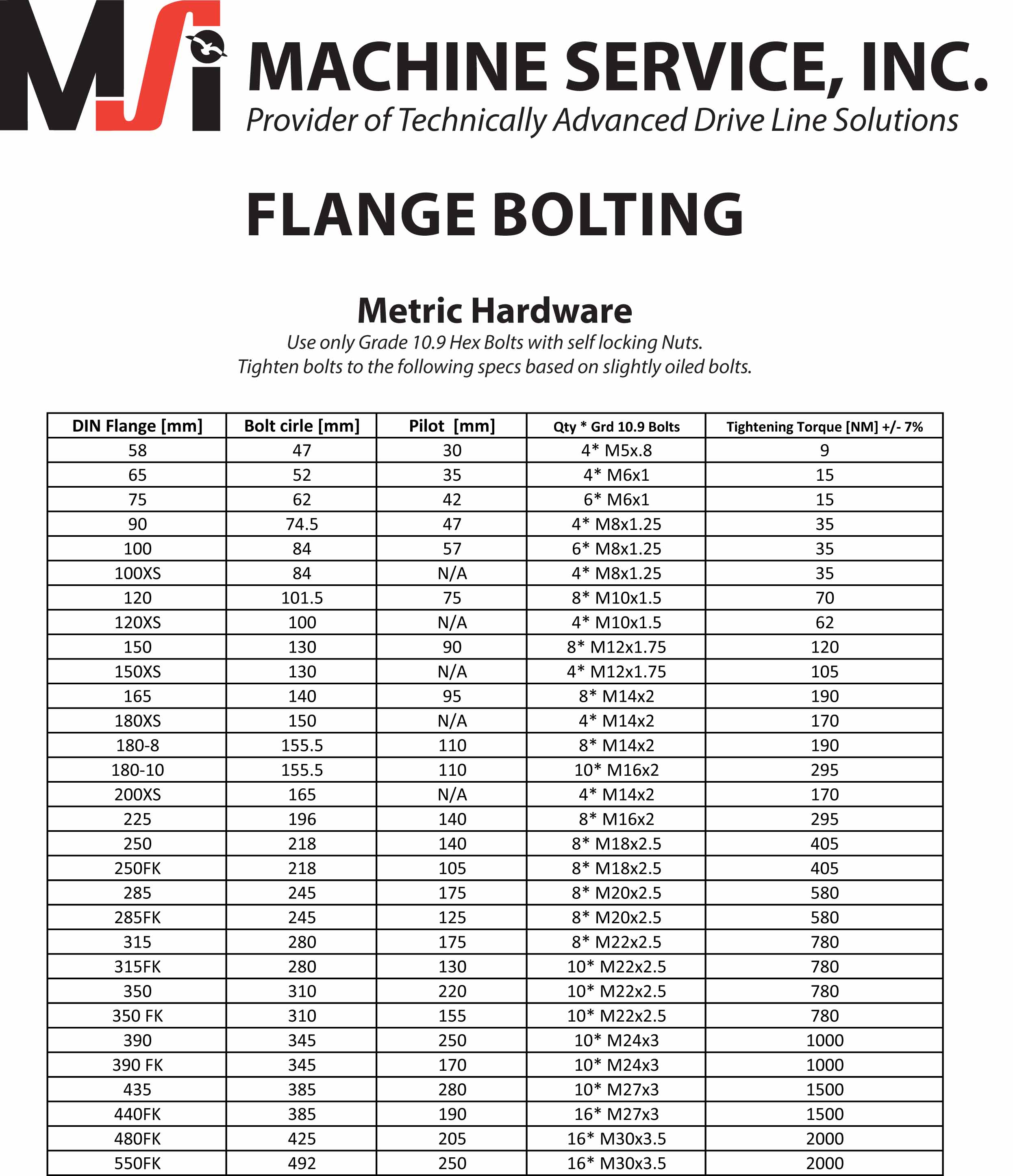

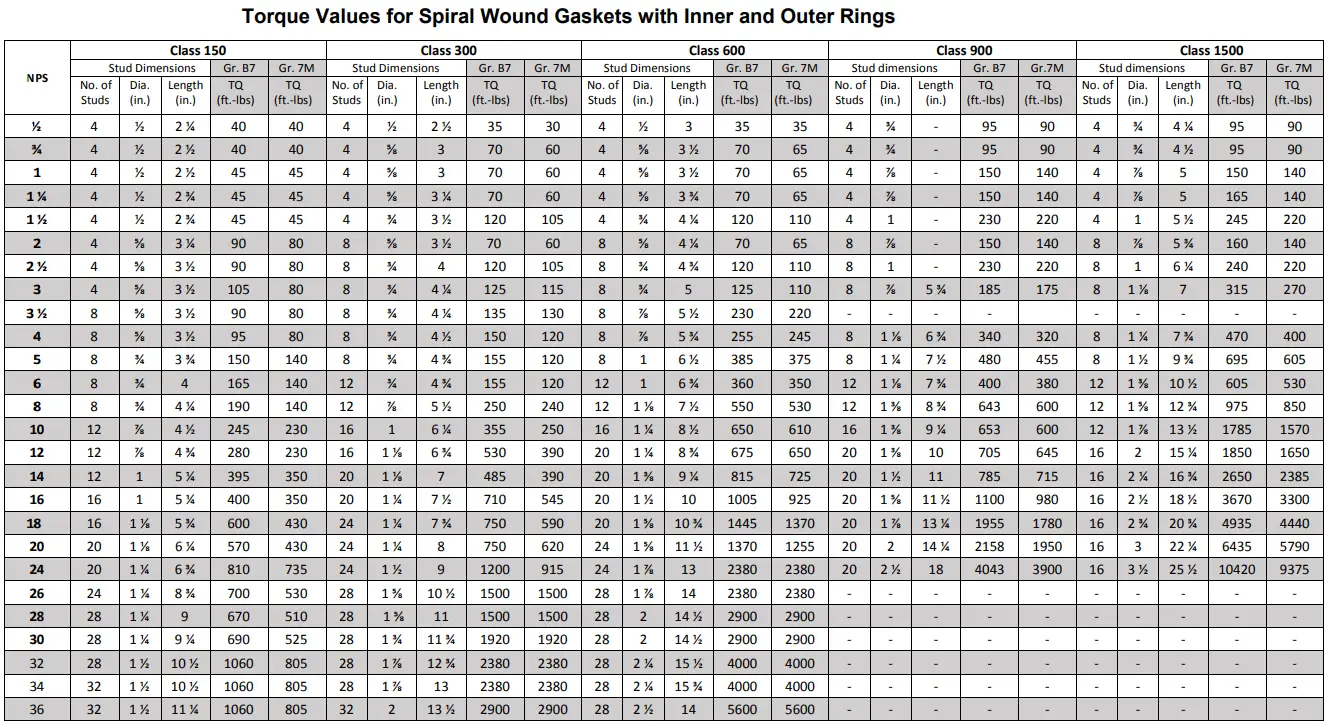

The recently published, awwa manual m11 includes a description of calculating torque values for When the gasket extends past the o.d. Web class 600 flange torque charts listed by nominal pipe size. X pitch x bolthole 10 din 75 50 4 x 11 90 60 4 x 14 90 60 4 x 14 90 60 4 x 14 90 60 4 x 14 Before using a given torque table, these assumptions should be verified to insure they are appropriate for the specific application. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. To achieve a reliable seal, adequate gasket stress must be applied Web bolt yield should be at least 80,000 psi. Web pipe size of bolts torque torque torque torque torque torque torque torque torque torque (inches) bolts (inches) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) 0.5 4 0.50 16 47 9 52 8 42 11 37 18 53 0.75 4 0.63 28 84 15 88 14 68 20 67 31 92 1 4 0.63 38 114 19 115 17 84 27 89 34 102 Lbs ansi 150# flanges ansi 300# flanges ansi 600# flanges rec. Web ses 75% of the yield strength. Web a successful flange installation requires the proper amount of load applied to the gasket. X pitch x bolthole o.d. Web flange reference chart pn6 5k 125 lbs pn10 10k 150 lbs pn16 16k 300 lbs pn25 20k 300 lbs pn40 40k 600 lbs o.d. Sealing for a safer and greener tomorrow.

Web Ses 75% Of The Yield Strength.

In this article, you will learn about the torque sequence of pipe flanges. X pitch x bolthole 10 din 75 50 4 x 11 90 60 4 x 14 90 60 4 x 14 90 60 4 x 14 90 60 4 x 14 Web the torque tables are built on specific assumptions regarding bolt and nut factor. The conventional way to achieve that load is by applying a measured torque to the flange bolts.

Follow Flange Bolt Torque Values For Proper Tightness.

Torque tables for the installation of flat gaskets with standard asme flanges. Web in this article, we will learn the basics of flange bolt torque calculation and some of the typical torque values in a chart format. Flange bolt torque calculation formula. Web class 2500 flange torque charts listed by nominal pipe size.

Grade 2, 5, And 8 Values Are For Plated Bolts.

Web class 1500 flange torque charts listed by nominal pipe size. Sealing for a safer and greener tomorrow. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: To achieve a reliable seal, adequate gasket stress must be applied

The Recently Published, Awwa Manual M11 Includes A Description Of Calculating Torque Values For

Web pipe size of bolts torque torque torque torque torque torque torque torque torque torque (inches) bolts (inches) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) (ft.lbs.) 0.5 4 0.50 16 47 9 52 8 42 11 37 18 53 0.75 4 0.63 28 84 15 88 14 68 20 67 31 92 1 4 0.63 38 114 19 115 17 84 27 89 34 102 Of the flange by 1/4:” to 3/8”, stop tightening. 1135 psi hydro test pressure: Web a successful flange installation requires the proper amount of load applied to the gasket.