The root diameter is the diameter of the unthreaded portion of the lag bolt, and can typically be found printed on the bolt. Pilot holes help prevent the wood from splitting and make it easier to drive the bolt in. Web check your chart and slide over the corresponding lag screw size as in the row that lines up. There are a number of variables that may change the required pilot hole dimensions including: For softwood, the pilot hole sizes can be 40% to 70% of the shank diameter for wood with g≤0.5;

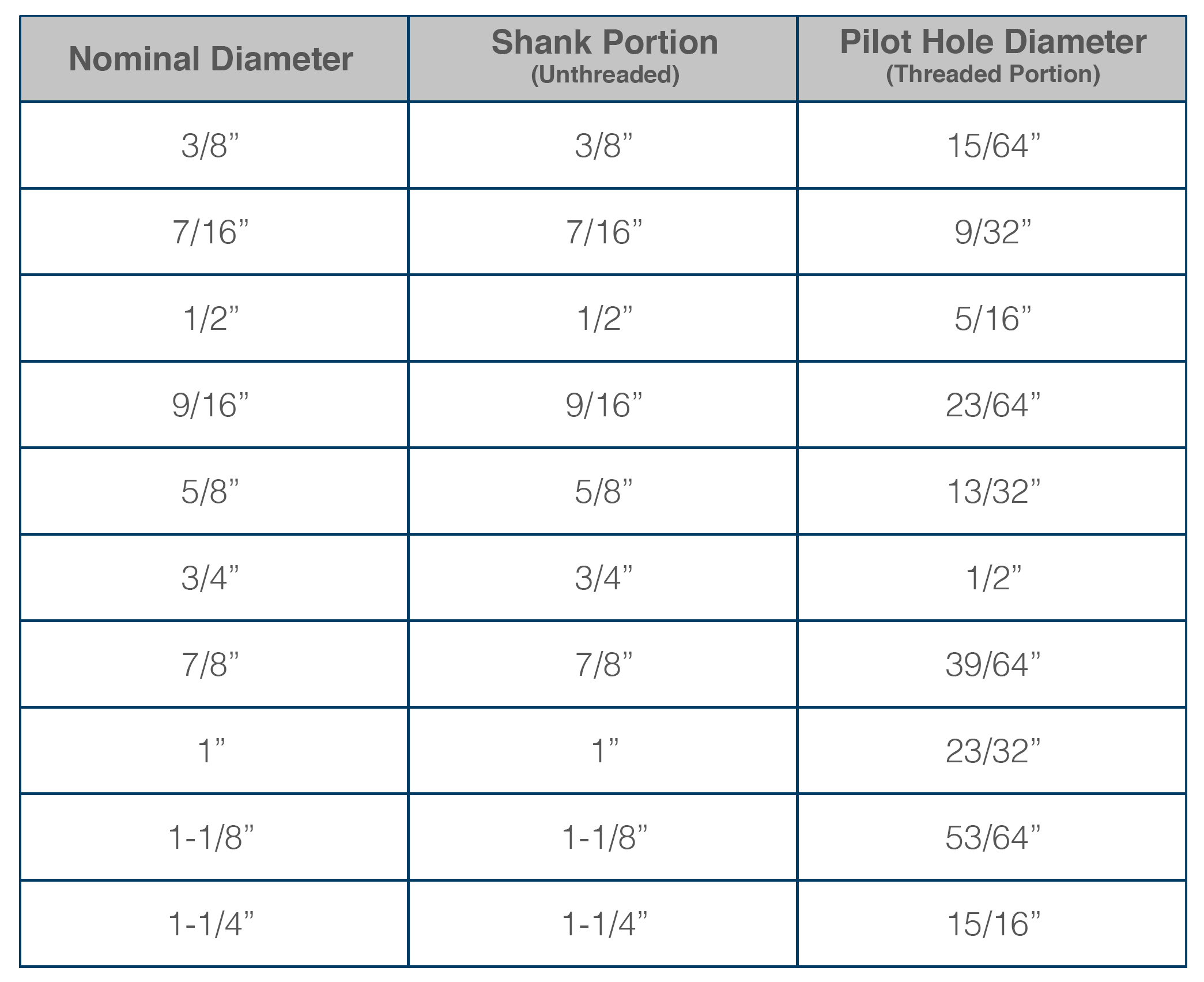

The easiest of these to address is wood type. Get your free downloadable chart of commonly accepted pilot hole sizes here. The vibration is apt to crumble the edges of the hole in the particleboard. Web a pilot hole size for lag bolts can vary depending on the diameter and length of the bolt. Web i found many charts that say the pilot hole size for a 5/8 lag is 13/32.

Hold the drill bit up in front of the screw. Web drilling a pilot hole and need to know what drill bit size to use? From there, you’ll be able to identify the head height, head width, and thread dimensions of the lag screw, with their subsequent minimum (min.) and maximum (max.) limits. The thread itself is 1/2”. I’d still go with the shank (minor diameter) as steve said.

The root part is around 3/8”. Choose a drill bit slightly smaller than the lag bolt's diameter. Checkout our chart for drilling lag screw pilot holes in softwoods & hardwoods. Web in this q. Web the proper size of the pilot is the size of the screw minus the threads. Without a perfect pilot hole, your project could collapse or cause damage to your materials. Once you have selected the proper drill bit, use your power drill to make a pilot hole through both of. Improve accuracy by providing a guide (or pilot) path for the screw to follow. The root diameter is the diameter of the unthreaded portion of the lag bolt, and can typically be found printed on the bolt. Web drilling a pilot hole and need to know what drill bit size to use? Bolt length, diameter, and wood species. Web let’s talk about how to determine the pilot hole sizes for lag screws. Pilot hole size can range as follows: Web the pilot hole is usually the diameter of the root of the thread and sometimes, for a bolt with a shank the beginning of the hole is taken out to that diameter. Web check your chart and slide over the corresponding lag screw size as in the row that lines up.

Web Let’s Talk About How To Determine The Pilot Hole Sizes For Lag Screws.

For hardwood, the pilot hole sizes can be 65% to 85% of the shank diameter for wood with g>0.6. Web view our chart for drilling pilot holes for lag bolt shield anchors. Pilot holes help prevent the wood from splitting and make it easier to drive the bolt in. Checkout our chart for drilling lag screw pilot holes in softwoods & hardwoods.

Lag Screws Are Fully Threaded And Come With Coarse Threads That Are Widely Separated:

Soft wood 40% to 70% of the shank diameter for wood with g ≤ 0.5. Generally, the pilot hole size should match the root diameter of the threaded portion of the bolt. In some cases, even that is very snug. The vibration is apt to crumble the edges of the hole in the particleboard.

Choose A Drill Bit Slightly Smaller Than The Lag Bolt's Diameter.

The easiest of these to address is wood type. Pilot hole size can range as follows: From there, you’ll be able to identify the head height, head width, and thread dimensions of the lag screw, with their subsequent minimum (min.) and maximum (max.) limits. Variables such as wood type, bolt length and bolt diameter all factor into ideal pilot hole sizes.

The Root Diameter Is The Diameter Of The Unthreaded Portion Of The Lag Bolt, And Can Typically Be Found Printed On The Bolt.

When the shank disappears behind the drill bit and all you see is threads then you have the right pilot hole size. The pilot hole will nestle the screw, making sure it remains securely in place. The easiest way to size them is to hold the screw up to the light. For softwood, the pilot hole sizes can be 40% to 70% of the shank diameter for wood with g≤0.5;