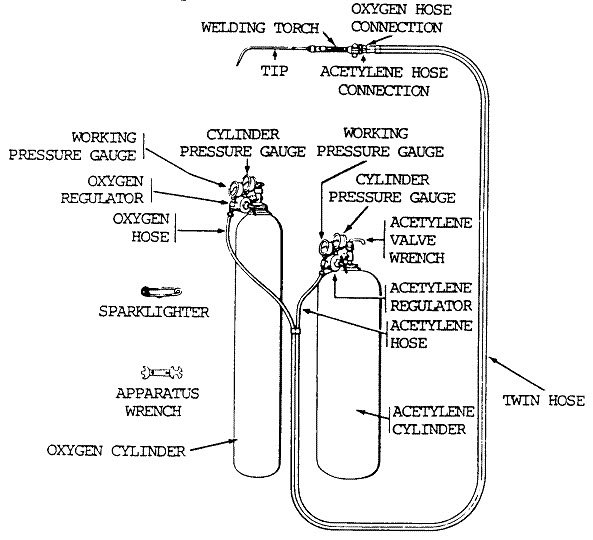

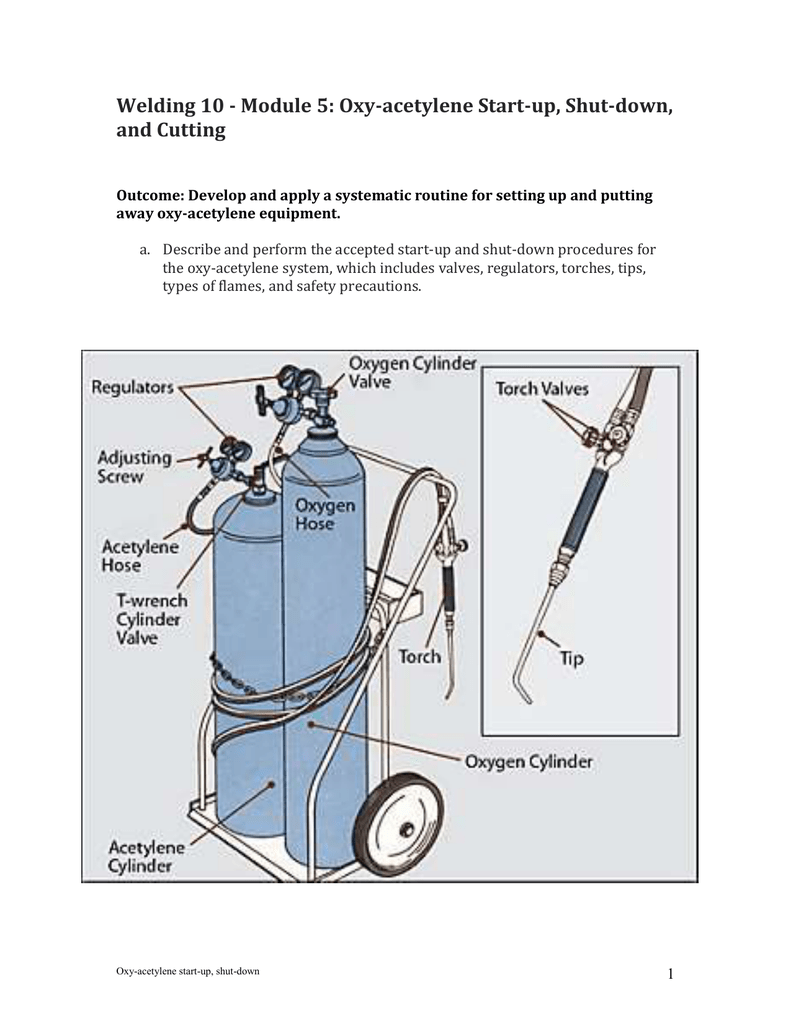

Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Increase regulator pressures if longer hose. Open the oxygen valve present on the welding torch. This is determined by the brand. Do you happen to know which type seat is most.

Increase regulator pressures if longer hose. Web ignite flame with striker. Find out the safety precautions, gas pressures, flame characteristics,. Open the oxygen valve present on the welding torch. This is especially important for oxygen cylinder connections.

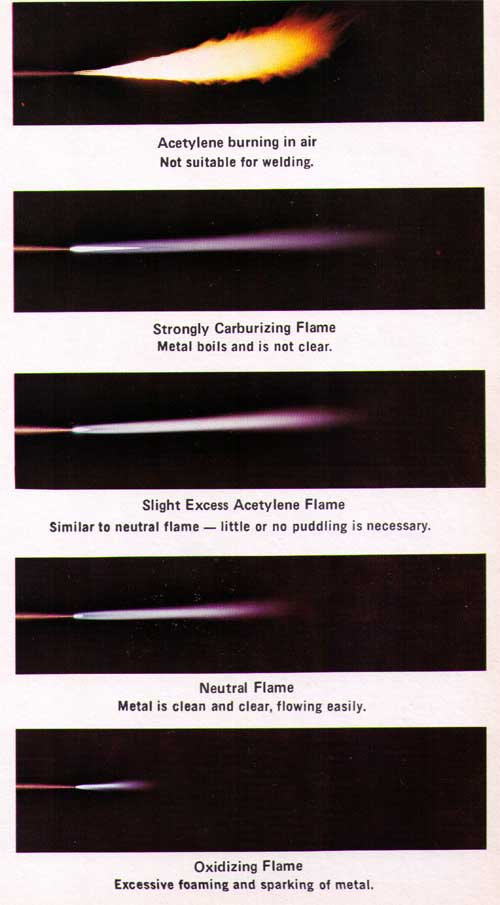

This is especially important for oxygen cylinder connections. Everyone in the hvac/r trade uses some type of torch to braze or solder alloys together. Web learn how to set up and use oxy acetylene welding equipment, including pressure, flame types, rods, and kit. It utilizes a mixture of oxygen. Decrease until flame goes back to tip.

Web there's lots of info in that chart but i still have two questions: Decrease until flame goes back to tip. Do you happen to know which type seat is most. The tip size is determined by the orifice for cutting oxygen gas. Find out the advantages, disadvantages, and. This is especially important for oxygen cylinder connections. · make sure torch valves are closed! You must know the manufacturer or model of your torch and/or the part number of the cutting tips you want to replace as this. Web learn how to set up and use oxy acetylene welding equipment, including pressure, flame types, rods, and kit. Make use of correct welding & cutting technique. Find out the basics, gas pressure settings, cutting techniques, and maintenance tips. Open the oxygen valve present on the welding torch. There are a number of different types of oxy. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches.

Find Out The Basics, Gas Pressure Settings, Cutting Techniques, And Maintenance Tips.

Find out the safety precautions, gas pressures, flame characteristics,. It utilizes a mixture of oxygen. 1) the table lists victor, harris, and airco seat types. This will depend on the thickness of the metal you are welding, as well as the type of joint you.

Decrease Until Flame Goes Back To Tip.

Web learn how to set up and use oxy acetylene welding equipment, including pressure, flame types, rods, and kit. Web there's lots of info in that chart but i still have two questions: Web learn how to set up and use an oxy acetylene cutting torch for various metals. This is especially important for oxygen cylinder connections.

So, What Is The Proper Way To Handle An.

Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. · make sure regulator pressure adjustment screws are backed out! Open the oxygen valve present on the welding torch. The tip size is determined by the orifice for cutting oxygen gas.

Web The First Step In Setting Up Your Oxy Acetylene Rosebud Torch Is To Choose The Right Tip.

You must know the manufacturer or model of your torch and/or the part number of the cutting tips you want to replace as this. This guideline will let you. This is determined by the brand. Adjust to the correct flame setting.