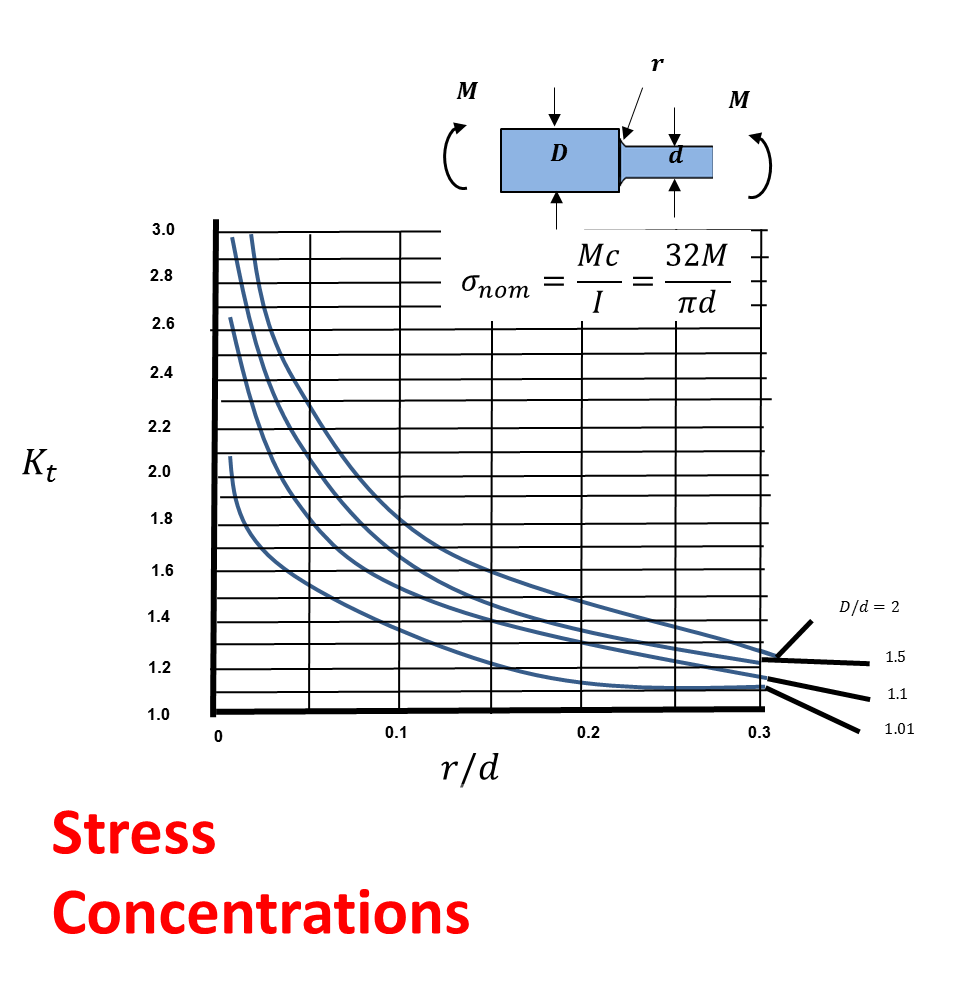

Preface for the third edition. The nominal bending stress is σ0 = m/znet where z net is a reduced value of the section modulus and is defined by z net = πa 32d (d4 −d4. 1 definitions and design relations. Web this situation of high stresses near dimensional changes and discontinuities of a member (holes, sharp corners, cracks etc.) is called stress concentration. As the radius of curvature approaches zero, the maximum stress approaches infinity.

Web index to the stress concentration factors. The nominal bending stress is σ0 = m/znet where znet is a reduced value of the section modulus and is defined by znet = πa 32 d (d4 −d4). Web in this tutorial, we will examine the standard method of accounting for stress concentrations caused by geometric features. 1 definitions and design relations. We offer a free version of this software.

Web to account for the peak in stress near a stress raiser, the stress concentration factor or theoretical stress concentration factor is defined as the ratio of the calculated peak stress to the nominal stress that would exist in the member if the distribution of stress 1 definitions and design relations. Web use this stress concentration factor calculator to estimate the localized high stresses in the regions of geometric discontinuities. Web this situation of high stresses near dimensional changes and discontinuities of a member (holes, sharp corners, cracks etc.) is called stress concentration. The nominal bending stress is σ0 = m/znet where znet is a reduced value of the section modulus and is defined by znet = πa 32 d (d4 −d4).

As the radius of curvature approaches zero, the maximum stress approaches infinity. Τ0 = tc/j, where c = d/2 and j = πd4/32. Web this situation of high stresses near dimensional changes and discontinuities of a member (holes, sharp corners, cracks etc.) is called stress concentration. We offer a free version of this software. The ratio of peak stress near stress riser to average stress over the member is called stress concentration factor. Web index to the stress concentration factors. Preface for the third edition. Accuracy of stress concentration factors. Σ0 = f/a, where a = πd2/4. Preface for the second edition. Web to account for the peak in stress near a stress raiser, the stress concentration factor or theoretical stress concentration factor is defined as the ratio of the calculated peak stress to the nominal stress that would exist in the member if the distribution of stress The nominal bending stress is σ0 = m/znet where z net is a reduced value of the section modulus and is defined by z net = πa 32d (d4 −d4. Web in this tutorial, we will examine the standard method of accounting for stress concentrations caused by geometric features. Web use this stress concentration factor calculator to estimate the localized high stresses in the regions of geometric discontinuities. Web the stress concentration calculator provides a set of interactive plots for common stress concentration factors.

As The Radius Of Curvature Approaches Zero, The Maximum Stress Approaches Infinity.

Web this situation of high stresses near dimensional changes and discontinuities of a member (holes, sharp corners, cracks etc.) is called stress concentration. Accuracy of stress concentration factors. Web the stress concentration calculator provides a set of interactive plots for common stress concentration factors. The nominal bending stress is σ0 = m/znet where z net is a reduced value of the section modulus and is defined by z net = πa 32d (d4 −d4.

Web Index To The Stress Concentration Factors.

Web to account for the peak in stress near a stress raiser, the stress concentration factor or theoretical stress concentration factor is defined as the ratio of the calculated peak stress to the nominal stress that would exist in the member if the distribution of stress Web use this stress concentration factor calculator to estimate the localized high stresses in the regions of geometric discontinuities. We offer a free version of this software. Web in this tutorial, we will examine the standard method of accounting for stress concentrations caused by geometric features.

1 Definitions And Design Relations.

The nominal bending stress is σ0 = m/znet where znet is a reduced value of the section modulus and is defined by znet = πa 32 d (d4 −d4). Τ0 = tc/j, where c = d/2 and j = πd4/32. The ratio of peak stress near stress riser to average stress over the member is called stress concentration factor. Preface for the third edition.

Σ0 = F/A, Where A = Πd2/4.

Preface for the second edition.