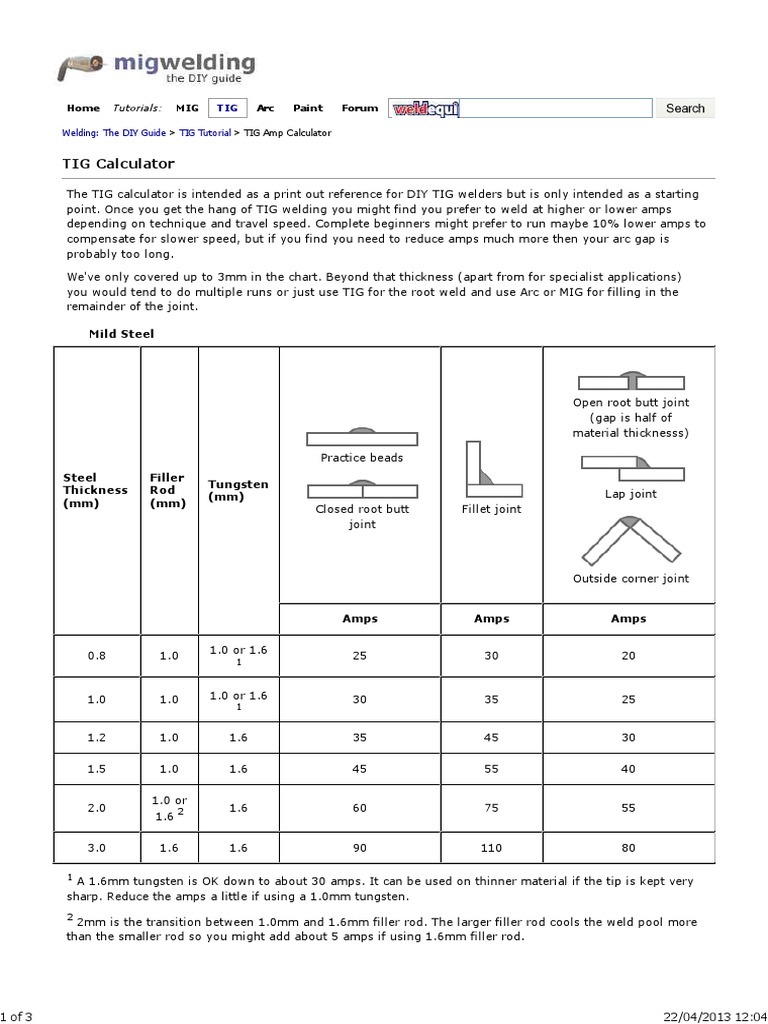

Follow the corresponding row and column to find the recommended settings. It lists recommended amperages for different weld joint types and thicknesses. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. According to these charts, mild steel requires the most amperage (not aluminum), and also the fastest travel speed. For beginners it’s recommended to stick with a 3/32” diameter tungsten.

Web i have three charts here, all from the same source (ck worldwide technical specifications for tig welding), but they seem to contradict everything i've heard. They can then look up the recommended settings on the chart and adjust their welding machine accordingly. By following the chart’s recommended settings, welders can achieve optimal weld quality. Web to use the tig welding chart, the welder must determine the material’s type and thickness. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together.

Web what metal are you welding? Follow the corresponding row and column to find the recommended settings. Stainless steel and aluminium amps chart. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Web i have three charts here, all from the same source (ck worldwide technical specifications for tig welding), but they seem to contradict everything i've heard.

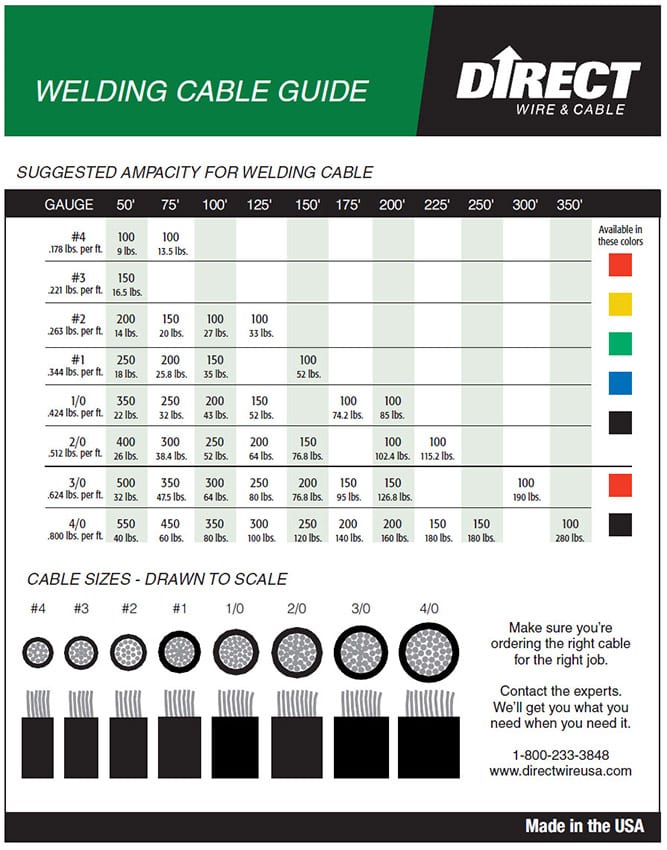

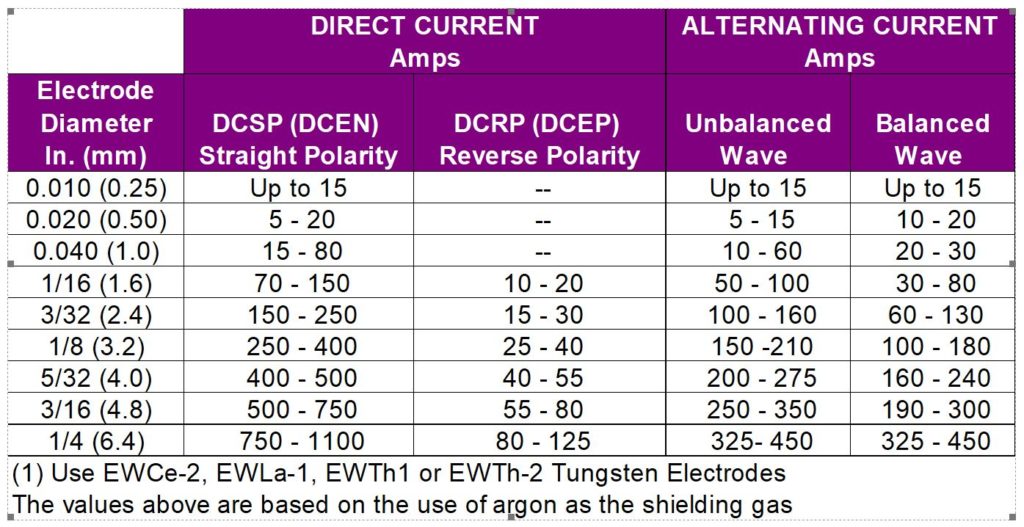

Web i have three charts here, all from the same source (ck worldwide technical specifications for tig welding), but they seem to contradict everything i've heard. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Other metals will have slightly different requirements. Web mainly on the material thickness and the amperage needed to achieve a proper weld. Web light gauge metals less than 1/16 (1.6mm) thick should always be welded with dcsp using argon gas. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. There might be variations with the settings depending on the manufacturer. The charts are intended as a starting point for beginner and intermediate tig welders. According to these charts, mild steel requires the most amperage (not aluminum), and also the fastest travel speed. Web this document provides a tig welding amp calculator chart for mild steel and stainless steel. Web empower your tig welding projects with our free online tig welding calculator. It lists recommended amperages for different weld joint types and thicknesses. Stainless steel and aluminium amps chart. Thicker materials will require more current and thus bigger tungsten. Use only stainless steel tools and brushes, keep stainless from coming in contact with other metals.

Other Metals Will Have Slightly Different Requirements.

Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. Web i have three charts here, all from the same source (ck worldwide technical specifications for tig welding), but they seem to contradict everything i've heard. The chart is intended as a starting point, as experienced welders may prefer higher or lower amperages depending on technique and travel speed. See the chart below for current ranges of all sizes.

Web Sheet Metal Is Defined As A Metal That Is Less Than 0.06 Inches Or 1.5 Millimeters In Thickness And Can Include Aluminum, Stainless Steel, And Mild Steel.

I'm in the process of making a welding table and i've burned a few holes on the 1 1/2 0.95 square iron i'm using for the frame of. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Web mainly on the material thickness and the amperage needed to achieve a proper weld. You can get more precise estimates with this online calculator from miller electric, but we are going to go over the basics to help you understand those estimates.

For Beginners It’s Recommended To Stick With A 3/32” Diameter Tungsten.

Web the size of the tig welding rod, also known as the filler metal, is determined by the thickness of the material being welded and the desired strength of the weld. Web printable charts shiowing the amps and tungstons you might select for various thiknesses, joint types and materials. Web using a welding amperage chart is an effective way to determine the appropriate amperage range for different welding applications. The charts are intended as a starting point for beginner and intermediate tig welders.

Browse Suggested Weld Parameter Settings For Tig Welding.

Follow the normal precautions for welding stainless such as: Web this document provides a tig welding amp calculator chart for mild steel and stainless steel. It lists recommended amperages for different weld joint types and thicknesses. Web although midwest tungsten service only provides 1/16, 3/32, and 1/8 electrodes, some projects call for a slightly bigger diameter, such as 5/32 or 3/16.